All-Inclusive Factory Service Technical manual for Hitachi Wheel Excavators Models Zaxis 170W-3 and Zaxis 190W-3.

This manuals will assist you in diagnosing, repairing, troubleshooting, performing perfomance checks, repairing engine, maintaining, operating, and other for your wheel excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 170W-3

Zaxis 190W-3

The manual comprises 15 documents, including the Workshop Manual, two Troubleshooting Manuals, Perfomance Check and Troubleshooting Manual, two Engine Technical Manuals, Maintenance Manual, three Operational Principle Manuals, two Operators Manuals, two Wiring Diagrams, and Aditional Service Information

1. Workshop Manual (WCGB-E-00-SP)

Format: PDF, 604 pages

Language: English

Table of Contents:

GENERAL

Precautions for Disassembling and Assembling

Tightening

Painting

Bleeding Air from Hydraulic Oil Tank

UPPERSTRUCTURE

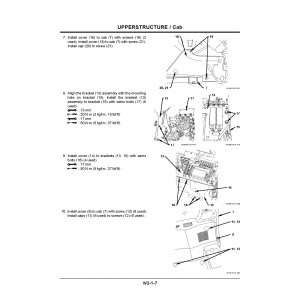

Cab

Counterweight

Main Frame

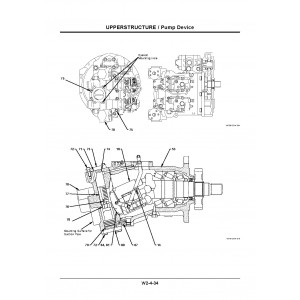

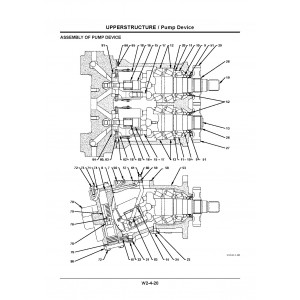

Pump Device

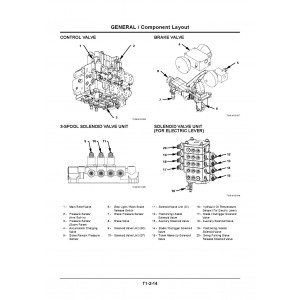

Control Valve

Swing Device

Pilot Valve

Electric Lever

Signal Control Valve

Shockless Valve

Solenoid Valve

Pilot Shut-Off Solenoid Valve

Steering Valve

Brake Valve

Accumulator Charge Valve

UNDERCARRIAGE

Swing Bearing

Travel Motor

Center Joint

Transmission

Axle

Axle Lock Cylinder

Operate Check Valve

Solenoid Valve

Transmission Changeover Solenoid Valve

Propeller Shaft

FRONT ATTACHMENT

Front Attachment

Cylinder

Hose Rupture Valve

Operate Check Valve

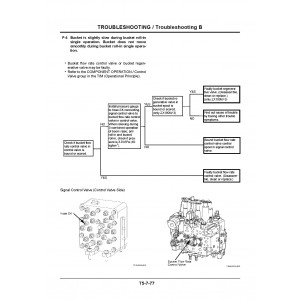

2. Troubleshooting Manual (TTCGB-E-00-SP)

Format: PDF, 576 pages

Language: English

Table of Contents:

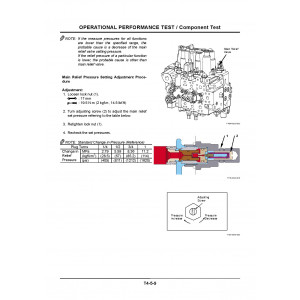

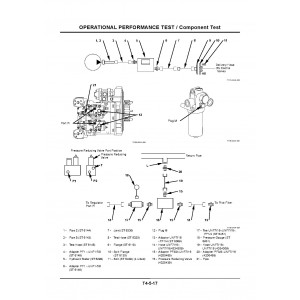

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Componebt Test

TROUBLESHOOTING

Diagnosing Procedure

Monitor Unit

Component Layout

Troubleshooting A

Troubleshooting B

Electrical System Inspection

3. Troubleshooting Manual (TTCGB-E-00)

Format: PDF, 624 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Componebt Test

TROUBLESHOOTING

Diagnosing Procedure

Monitor Unit

Dr. ZX

ICF

Component Layout

Troubleshooting A

Troubleshooting B

Electrical System Inspection

4. Perfomance Check and Troubleshooting Manual (TTLA-0722-ZX)

Format: PDF, 148 pages

Language: English

Table of Contents:

T04_OPERATIONAL PERFORMANCE TEST

Introduction

T05_TROUBLESHOOTING

Diagnosing Procedure

Diagnosing Procedure

Monitor Unit

Dr.ZX

ICF

Component Layout

5. Engine Technical Manual (KM-4HK1-E-02)

Format: PDF, 548 pages

Language: English

Table of Contents:

Control System

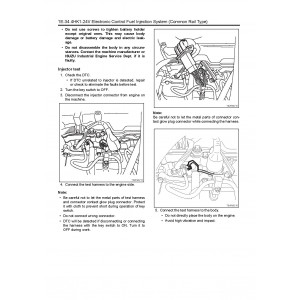

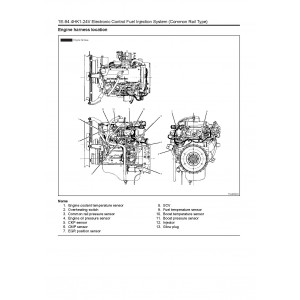

4HK1-24V Electronic Control Fuel Injection System (Common Rail Type)

How to Use This Manual

Precautions on Service Work

Procedure of Trouble Diagnosis

How to Inspect Injector

How to Use Breaker Box

Engine Control System

List of Function Checks

List of Diagnostic Trouble Codes

List of Trouble Symptom

Special Tool

6. Engine Technical Manual (KM-4HK1_6HK1-E-03)

Format: PDF, 362 pages

Language: English

Table of Contents:

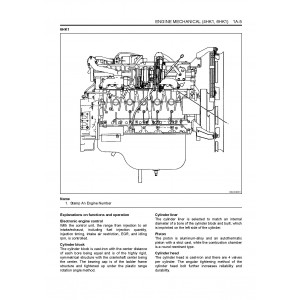

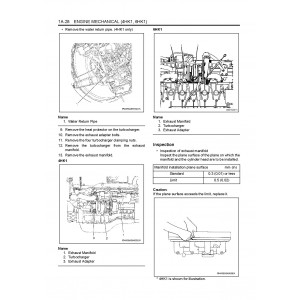

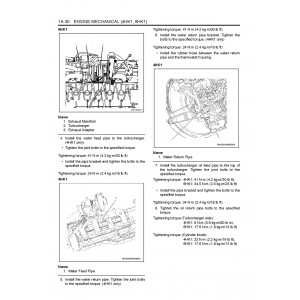

ENGINE MECHANICAL (4HK1, 6HK1)

ISUZU DIESEL ENGINE (4HK1, 6HK1)

Cylinder Head Cover

Inlet Cover

Turbocharger and Exhaust Manifold

Timing Gear Train

Rocker Arm Shaft ASM

Camshaft ASM

Valve Stem Seal, Valve Spring

Cylinder Head

Piston, Connecting Rod

Flywheel

Front Cover

Crankshaft Front Oil Seal

Crankshaft Rear Oil Seal

Crankshaft

Cylinder Block

Lubrication System

Oil Port Cover ASM

Oil Cooler

Oil Pan

Oil Pump

Oil Pressure Switch

Cooling System

Cooling System

Water Pump (4HK1)

Water Pump (4HK1 with High Fan Model)

Water Pump (6HK1)

Thermostat

Drive Belt

High Fan

Fuel System

Fuel System

Fuel Filter ASM

Fuel Filter Element

Fuel Injector

Fuel Supply Pump (4HK1)

Fuel Supply Pump (6HK1)

Strainer, Gauze filter

Suction Control Valve

Electromagnetic Pump Filter

Common Rail

Engine Electrical

Service Precautions

Charging System

Generator (4HK1)

Generator (6HK1)

Disassembly and Inspection of Generator

Starting System

Starter (4HK1)

Starter (6HK1)

Disassembly and Inspection of Starter

Assembly of Starter

Preheating System

Exhaust System

EGR System

EGR Valve and EGR Cooler

Exhaust System

Turbocharger (6HK1)

Turbocharger (4HK1)

Measurement Tool

Other Material

7. Maintenance Manual (TTLA0735)

Format: PDF, 213 pages

Language: English

Table of Contents:

MAINTENANCE

Correct Maintenance and Inspection Procedures

Check the Hour Meter Regularly

Use Correct Fuels and Lubricants

Layout

Maintenance Guide Table

Prepare Machine for Maintenance

Hood and Access Covers

Periodic Replacement of Parts

Maintenance Guide

HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT

Hydraulic Circuit

Electrical Circuit

Electrical Diagram

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

Maintenance Under Special Environmental Conditions

STORAGE

Storing the Machine

Removing the Machine from Storage

TROUBLESHOOTING

Troubleshooting

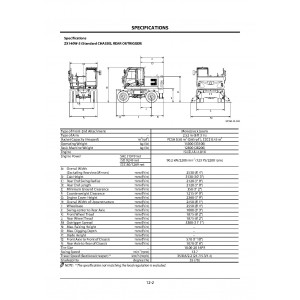

SPECIFICATIONS

Specifications (ZAXIS140W-3) (Standard CHASSIS, REAR BLADE)

Specifications (ZAXIS140W-3) (Standard CHASSIS, REAR OUTRIGGER)

Specifications (ZAXIS140W-3) (FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS140W-3) (FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS140W-3) (FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS140W-3 MONOBLOCK BOOM

Working Ranges ZAXIS140W-3 2-PIECE BOOM

Specifications (ZAXIS170W-3) (Standard GAUGE, Standard CHASSIS, REAR BLADE)

Specifications (ZAXIS170W-3) (Standard GAUGE, Standard CHASSIS, REAR OUTRIGGER)

Specifications (ZAXIS170W-3 (Standard GAUGE, FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS170W-3) (Standard GAUGE, FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS170W-3) (Standard GAUGE, FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS170W-3 MONOBLOCK BOOM

Working Ranges ZAXIS170W-3 2-PIECE BOOM

Specifications (ZAXIS190W-3 )(Standard CHASSIS, REAR BLADE)

Specifications (ZAXIS190W-3) (Standard CHASSIS, REAR OUTRIGGER)

Specifications (ZAXIS190W-3) (FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS190W-3) (FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS190W-3) (FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS190W-3 MONOBLOCK BOOM

Working Ranges ZAXIS190W-3 2-PIECE BOOM

Specifications (ZAXIS210W-3) (Standard GAUGE, REAR BLADE)

Specifications (ZAXIS210W-3) (Standard GAUGE, REAR OUTRIGGER)

Specifications (ZAXIS210W-3) (Standard GAUGE, FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS210W-3) (Standard GAUGE, FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS210W-3) (Standard GAUGE, FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS210W-3 MONOBLOCK BOOM

Working Ranges ZAXIS210W-3 2-PIECE BOOM

Sound Level Results (2000/14/EC)

OPTIONAL ATTACHMENTS AND DEVICES

Blade and Outrigger

Maintenance

2-Piece Boom

Maintenance (2-piece Boom)

Lifting Capacities (ZAXIS140W-3)

Lifting Capacities (ZAXIS170W-3)

Lifting Capacities (ZAXIS190W-3)

Lifting Capacities (ZAXIS210W-3)

8. Operational Principle Manual (TTLA-0721-ZX)

Format: PDF, 483 pages

Language: English

Table of Contents:

T01_GENERAL

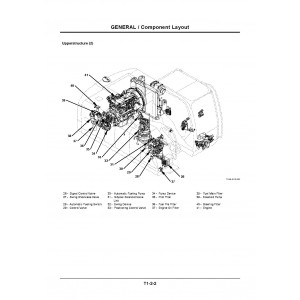

Component Layout

T02_SYSTEM

Controller

Control System

ECM System

Hydraulic System

Electrical System

T03_COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Electric Lever

Transmission

Axle

Travel Motor

Signal Control Valve

Steering Valve

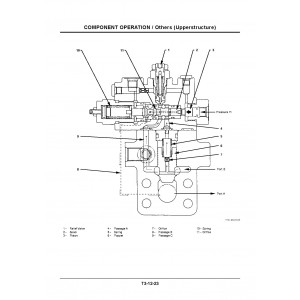

Others (Upperstructure)

Others (Undercarriage)

9. Operational Principle Manual (TOCGB-E-00-SP)

Format: PDF, 530 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

Component Specifications

SYSTEM

Controller

Control System

ECM System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Electric Lever

Transmission

Axle

Travel Motor

Signal Control Valve

Steering Valve

Brake Valve

Others (Upperstructure)

Others (Undercarriage)

10. Operational Principle Manual (TOCGB-E-00)

Format: PDF, 530 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

Component Specifications

SYSTEM

Controller

Control System

ECM System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Electric Lever

Transmission

Axle

Travel Motor

Signal Control Valve

Steering Valve

Brake Valve

Others (Upperstructure)

Others (Undercarriage)

11. Operators Manual (TTLA0734)

Format: PDF, 161 pages

Language: English

Table of Contents:

OPERATION

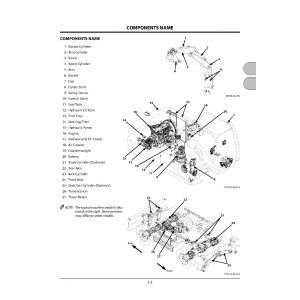

COMPONENTS NAME

Cab Features (Standard Model)

Steering Column Console

Steering Wheel and Travel Horn Switch

Accelerator Pedal

Brake Pedal

Forward/Reverse Travel Switch

Combination Switch(Turn Signal Switch, Light and Dimmer Switches)

Brake Switch

Hazard Switch

Operator’s Station

Key Switch

Right/Left Control Levers

Lever Switch

Lighter

Cab Light

Installing Fire Extinguisher (Optional)

Pilot Control Shut-off Lever

Engine Stop Switch

Multi Function Monitor

Basic Screen

Monitor Operation

Displaying Basic Screen

Trip Meter (7)

Odometer (8)

Hour Meter (9)

Clock (18)

Fuel Gauge (25)

Coolant Temperature Gauge (30)

Brake Oil Pressure Gauge (33)

Travel Speed Meter (34)

Tachometer (35)

Back Monitor Screen Selector (22)

Menu Key (23)

Optional Function Keys (24, 27, 29 and 31)

Return-basic Screen Key (32)

Menu Screen

Displaying Basic Screen by Inputting Password (Optional)

Corrective Measures to be Taken when a Wrong Password is input

Extending Password Validity Time

Alarm Occurrence Screen

Clock Setting

Work Mode (Attachment Selection)

Attachment Adjustment (Pump 2 Flow Rate Adjustment)

Operating Status

Maintenance Setting

Mail (Optional)

Meter Display Control

Password Revising (Optional)

Back Monitor Setting

Language Setting

Meter Combination Setting

Unit Setting

Fuse Box

Additional Fuse Box

Auto Air Conditioner Operation

Tips for Optimal Air Conditioner Usage

Heater (Optional) Operation

Am/Fm Radio Operation

Digital Clock Setting Procedure

Cab Door Release Lever

Opening Upper Front Window

Closing Upper Front Window

Removing and Storing Lower Front Window

Opening Door Windows

Opening/Closing Overhead Window (Std. Model)

Opening/Closing Polycarbonate Type Roof Overhead Window (Clear Hatch: If Equipped)

Emergency Exit

Adjusting the Air-suspension Seat (Optional)

Seat with a Built-in Heater

Adjusting the Air-suspension Seat(Optional)

Seat with a Built-in Heater

Seat Belt

BREAK-IN

Observe Engine Operation Closely

Every 8 Hours or Daily

After the First 50 Hours

After the First 100 Hours

OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Before Starting Engine

Starting the Engine in Ordinary Temperature

Starting in Cold Weather

Check Instruments After Starting

Using Booster Batteries

Stopping the Engine

DRIVING THE MACHINE

Traveling

Engine Speed Control

Travel Mode Switch

Stopping and Restarting

Instructions for Traveling on a Slope

Parking

Emergency Parking Due to Machine Failure

Travel Alarm (Optional)

OPERATING THE MACHINE

Control Lever (ISO Pattern) (Standard)

Control Lever (Hitachi Pattern)

Pilot Control Shut-off Lever

Steering Wheel Column

Warming-up Operation

Engine Speed Control

Auto-idle

Work Mode

Power Digging (Only ZAXIS210W-3)

Power Mode

Parking/Stopping the Machine on a Slope (In Case of Emergency)

Raising the Machine Front Above the Ground with the Boom and Arm Function

Excavation

Face Shovel Operation

Grading Operation

Do Not Slam the Bucket Teeth into the Ground

Do Not Use the Bucket as a Hammer

Avoid Increasing Digging Force Forcibly

Avoid Using Swing Power

Boom Lowering Procedure in Emergency or when the Engine Stalls

Overnight Storage Instructions

TRANSPORTING

Transporting by Road

Loading/Unloading on a Trailer

Transporting

Unloading

Towing Machine

12. Operators Manual (EMCGB-1-2)

Format: PDF, 369 pages

Language: English

Table of Contents:

INTRODUCTION

INDEX

MACHINE NUMBERS

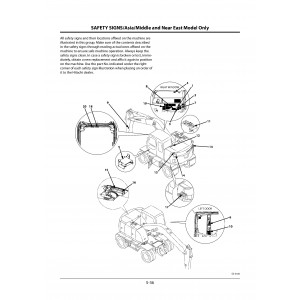

SAFETY

SAFETY SIGNS

COMPONENTS NAME

OPERATORS STATION

BREAK-IN

OPERATING THE ENGINE

DRIVING THE MACHINE

OPERATING THE MACHINE

TRANSPORTING

MAINTENANCE

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

OPTIONAL ATTACHMENTS AND DEVICES

INDEX

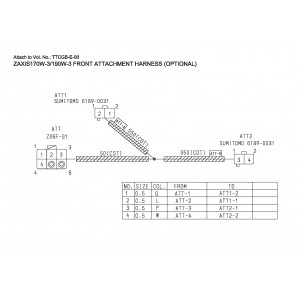

13. Wiring Diagram (TTCGB-E-00-circuit2)

Format: PDF, 14 pages

Language: English

Table of Contents:

ZAXIS170W-3/190W-3 FRONT ATTACHMENT HARNESS (OPTIONAL)

ZAXIS170W-3/190W-3 FLOW RATE SELECTOR HARNESS (OPTIONAL)

ZAXIS140W-3/170W-3/190W-3 SELECTOR VALVE / SECONDARY PILOT RELIEF SELECTOR HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 BOOM BOTTOM PRESSURE SENSOR HARNESS (OPTIONAL)

ZAXIS170W-3/190W-3 ASSIST HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 FLOW RATE ADJUSTMENT ASSIST HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 ASSIST HARNESS (1) (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 ASSIST HARNESS (2) (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 OVERLOAD ALARM HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 OVERLOAD ALARM SUB HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3GRIP EXTENSION HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3GRIP EXTENSION HARNESS (FNR)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 HEATER SEAT HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 AUTO-CRUISE HARNESS (OPTIONAL)

14. Wiring Diagram (TTCGB-E-00-circuit)

Format: PDF, 20 pages

Language: English

Table of Contents:

ELECTRICAL CIRCUIT DIAGRAM (STANDARD)

ELECTRICAL CIRCUIT DIAGRAM (OPTIONAL)

CONNECTORS

CAB HARNESS

ENGINE HARNESS

FLOOR HARNESS

MONITOR HARNESS

CHASSIS HARNESS

LEFT CONSOLE HARNESS

AUXILIARY / POSITIONING SELECT HARNESS

BLADE / OUTRIGGER HARNESS

LICENSE PLATE HARNESS

POSITIONING HARNESS

PRESSURE SENSOR (POSITIONING) HARNESS

SWING PARKING BRAKE RELEASE HARNESS

HYDRAULIC CIRCUIT DIAGRAM (2-PIECE BOOM, FULLY OPTIONAL)

HYDRAULIC CIRCUIT DIAGRAM (MONOBLOCK BOOM, FULLY OPTIONAL)

15. Aditional Service Information (ZX170W-3_add)

Language: English

This manuals will assist you in diagnosing, repairing, troubleshooting, performing perfomance checks, repairing engine, maintaining, operating, and other for your wheel excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 170W-3

Zaxis 190W-3

The manual comprises 15 documents, including the Workshop Manual, two Troubleshooting Manuals, Perfomance Check and Troubleshooting Manual, two Engine Technical Manuals, Maintenance Manual, three Operational Principle Manuals, two Operators Manuals, two Wiring Diagrams, and Aditional Service Information

1. Workshop Manual (WCGB-E-00-SP)

Format: PDF, 604 pages

Language: English

Table of Contents:

GENERAL

Precautions for Disassembling and Assembling

Tightening

Painting

Bleeding Air from Hydraulic Oil Tank

UPPERSTRUCTURE

Cab

Counterweight

Main Frame

Pump Device

Control Valve

Swing Device

Pilot Valve

Electric Lever

Signal Control Valve

Shockless Valve

Solenoid Valve

Pilot Shut-Off Solenoid Valve

Steering Valve

Brake Valve

Accumulator Charge Valve

UNDERCARRIAGE

Swing Bearing

Travel Motor

Center Joint

Transmission

Axle

Axle Lock Cylinder

Operate Check Valve

Solenoid Valve

Transmission Changeover Solenoid Valve

Propeller Shaft

FRONT ATTACHMENT

Front Attachment

Cylinder

Hose Rupture Valve

Operate Check Valve

2. Troubleshooting Manual (TTCGB-E-00-SP)

Format: PDF, 576 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Componebt Test

TROUBLESHOOTING

Diagnosing Procedure

Monitor Unit

Component Layout

Troubleshooting A

Troubleshooting B

Electrical System Inspection

3. Troubleshooting Manual (TTCGB-E-00)

Format: PDF, 624 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Componebt Test

TROUBLESHOOTING

Diagnosing Procedure

Monitor Unit

Dr. ZX

ICF

Component Layout

Troubleshooting A

Troubleshooting B

Electrical System Inspection

4. Perfomance Check and Troubleshooting Manual (TTLA-0722-ZX)

Format: PDF, 148 pages

Language: English

Table of Contents:

T04_OPERATIONAL PERFORMANCE TEST

Introduction

T05_TROUBLESHOOTING

Diagnosing Procedure

Diagnosing Procedure

Monitor Unit

Dr.ZX

ICF

Component Layout

5. Engine Technical Manual (KM-4HK1-E-02)

Format: PDF, 548 pages

Language: English

Table of Contents:

Control System

4HK1-24V Electronic Control Fuel Injection System (Common Rail Type)

How to Use This Manual

Precautions on Service Work

Procedure of Trouble Diagnosis

How to Inspect Injector

How to Use Breaker Box

Engine Control System

List of Function Checks

List of Diagnostic Trouble Codes

List of Trouble Symptom

Special Tool

6. Engine Technical Manual (KM-4HK1_6HK1-E-03)

Format: PDF, 362 pages

Language: English

Table of Contents:

ENGINE MECHANICAL (4HK1, 6HK1)

ISUZU DIESEL ENGINE (4HK1, 6HK1)

Cylinder Head Cover

Inlet Cover

Turbocharger and Exhaust Manifold

Timing Gear Train

Rocker Arm Shaft ASM

Camshaft ASM

Valve Stem Seal, Valve Spring

Cylinder Head

Piston, Connecting Rod

Flywheel

Front Cover

Crankshaft Front Oil Seal

Crankshaft Rear Oil Seal

Crankshaft

Cylinder Block

Lubrication System

Oil Port Cover ASM

Oil Cooler

Oil Pan

Oil Pump

Oil Pressure Switch

Cooling System

Cooling System

Water Pump (4HK1)

Water Pump (4HK1 with High Fan Model)

Water Pump (6HK1)

Thermostat

Drive Belt

High Fan

Fuel System

Fuel System

Fuel Filter ASM

Fuel Filter Element

Fuel Injector

Fuel Supply Pump (4HK1)

Fuel Supply Pump (6HK1)

Strainer, Gauze filter

Suction Control Valve

Electromagnetic Pump Filter

Common Rail

Engine Electrical

Service Precautions

Charging System

Generator (4HK1)

Generator (6HK1)

Disassembly and Inspection of Generator

Starting System

Starter (4HK1)

Starter (6HK1)

Disassembly and Inspection of Starter

Assembly of Starter

Preheating System

Exhaust System

EGR System

EGR Valve and EGR Cooler

Exhaust System

Turbocharger (6HK1)

Turbocharger (4HK1)

Measurement Tool

Other Material

7. Maintenance Manual (TTLA0735)

Format: PDF, 213 pages

Language: English

Table of Contents:

MAINTENANCE

Correct Maintenance and Inspection Procedures

Check the Hour Meter Regularly

Use Correct Fuels and Lubricants

Layout

Maintenance Guide Table

Prepare Machine for Maintenance

Hood and Access Covers

Periodic Replacement of Parts

Maintenance Guide

HYDRAULIC CIRCUIT AND ELECTRICAL CIRCUIT

Hydraulic Circuit

Electrical Circuit

Electrical Diagram

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

Maintenance Under Special Environmental Conditions

STORAGE

Storing the Machine

Removing the Machine from Storage

TROUBLESHOOTING

Troubleshooting

SPECIFICATIONS

Specifications (ZAXIS140W-3) (Standard CHASSIS, REAR BLADE)

Specifications (ZAXIS140W-3) (Standard CHASSIS, REAR OUTRIGGER)

Specifications (ZAXIS140W-3) (FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS140W-3) (FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS140W-3) (FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS140W-3 MONOBLOCK BOOM

Working Ranges ZAXIS140W-3 2-PIECE BOOM

Specifications (ZAXIS170W-3) (Standard GAUGE, Standard CHASSIS, REAR BLADE)

Specifications (ZAXIS170W-3) (Standard GAUGE, Standard CHASSIS, REAR OUTRIGGER)

Specifications (ZAXIS170W-3 (Standard GAUGE, FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS170W-3) (Standard GAUGE, FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS170W-3) (Standard GAUGE, FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS170W-3 MONOBLOCK BOOM

Working Ranges ZAXIS170W-3 2-PIECE BOOM

Specifications (ZAXIS190W-3 )(Standard CHASSIS, REAR BLADE)

Specifications (ZAXIS190W-3) (Standard CHASSIS, REAR OUTRIGGER)

Specifications (ZAXIS190W-3) (FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS190W-3) (FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS190W-3) (FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS190W-3 MONOBLOCK BOOM

Working Ranges ZAXIS190W-3 2-PIECE BOOM

Specifications (ZAXIS210W-3) (Standard GAUGE, REAR BLADE)

Specifications (ZAXIS210W-3) (Standard GAUGE, REAR OUTRIGGER)

Specifications (ZAXIS210W-3) (Standard GAUGE, FRONT BLADE REAR OUTRIGGER)

Specifications (ZAXIS210W-3) (Standard GAUGE, FRONT OUTRIGGER REAR BLADE)

Specifications (ZAXIS210W-3) (Standard GAUGE, FRONT OUTRIGGER REAR OUTRIGGER)

Working Ranges ZAXIS210W-3 MONOBLOCK BOOM

Working Ranges ZAXIS210W-3 2-PIECE BOOM

Sound Level Results (2000/14/EC)

OPTIONAL ATTACHMENTS AND DEVICES

Blade and Outrigger

Maintenance

2-Piece Boom

Maintenance (2-piece Boom)

Lifting Capacities (ZAXIS140W-3)

Lifting Capacities (ZAXIS170W-3)

Lifting Capacities (ZAXIS190W-3)

Lifting Capacities (ZAXIS210W-3)

8. Operational Principle Manual (TTLA-0721-ZX)

Format: PDF, 483 pages

Language: English

Table of Contents:

T01_GENERAL

Component Layout

T02_SYSTEM

Controller

Control System

ECM System

Hydraulic System

Electrical System

T03_COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Electric Lever

Transmission

Axle

Travel Motor

Signal Control Valve

Steering Valve

Others (Upperstructure)

Others (Undercarriage)

9. Operational Principle Manual (TOCGB-E-00-SP)

Format: PDF, 530 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

Component Specifications

SYSTEM

Controller

Control System

ECM System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Electric Lever

Transmission

Axle

Travel Motor

Signal Control Valve

Steering Valve

Brake Valve

Others (Upperstructure)

Others (Undercarriage)

10. Operational Principle Manual (TOCGB-E-00)

Format: PDF, 530 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

Component Specifications

SYSTEM

Controller

Control System

ECM System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Electric Lever

Transmission

Axle

Travel Motor

Signal Control Valve

Steering Valve

Brake Valve

Others (Upperstructure)

Others (Undercarriage)

11. Operators Manual (TTLA0734)

Format: PDF, 161 pages

Language: English

Table of Contents:

OPERATION

COMPONENTS NAME

Cab Features (Standard Model)

Steering Column Console

Steering Wheel and Travel Horn Switch

Accelerator Pedal

Brake Pedal

Forward/Reverse Travel Switch

Combination Switch(Turn Signal Switch, Light and Dimmer Switches)

Brake Switch

Hazard Switch

Operator’s Station

Key Switch

Right/Left Control Levers

Lever Switch

Lighter

Cab Light

Installing Fire Extinguisher (Optional)

Pilot Control Shut-off Lever

Engine Stop Switch

Multi Function Monitor

Basic Screen

Monitor Operation

Displaying Basic Screen

Trip Meter (7)

Odometer (8)

Hour Meter (9)

Clock (18)

Fuel Gauge (25)

Coolant Temperature Gauge (30)

Brake Oil Pressure Gauge (33)

Travel Speed Meter (34)

Tachometer (35)

Back Monitor Screen Selector (22)

Menu Key (23)

Optional Function Keys (24, 27, 29 and 31)

Return-basic Screen Key (32)

Menu Screen

Displaying Basic Screen by Inputting Password (Optional)

Corrective Measures to be Taken when a Wrong Password is input

Extending Password Validity Time

Alarm Occurrence Screen

Clock Setting

Work Mode (Attachment Selection)

Attachment Adjustment (Pump 2 Flow Rate Adjustment)

Operating Status

Maintenance Setting

Mail (Optional)

Meter Display Control

Password Revising (Optional)

Back Monitor Setting

Language Setting

Meter Combination Setting

Unit Setting

Fuse Box

Additional Fuse Box

Auto Air Conditioner Operation

Tips for Optimal Air Conditioner Usage

Heater (Optional) Operation

Am/Fm Radio Operation

Digital Clock Setting Procedure

Cab Door Release Lever

Opening Upper Front Window

Closing Upper Front Window

Removing and Storing Lower Front Window

Opening Door Windows

Opening/Closing Overhead Window (Std. Model)

Opening/Closing Polycarbonate Type Roof Overhead Window (Clear Hatch: If Equipped)

Emergency Exit

Adjusting the Air-suspension Seat (Optional)

Seat with a Built-in Heater

Adjusting the Air-suspension Seat(Optional)

Seat with a Built-in Heater

Seat Belt

BREAK-IN

Observe Engine Operation Closely

Every 8 Hours or Daily

After the First 50 Hours

After the First 100 Hours

OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Before Starting Engine

Starting the Engine in Ordinary Temperature

Starting in Cold Weather

Check Instruments After Starting

Using Booster Batteries

Stopping the Engine

DRIVING THE MACHINE

Traveling

Engine Speed Control

Travel Mode Switch

Stopping and Restarting

Instructions for Traveling on a Slope

Parking

Emergency Parking Due to Machine Failure

Travel Alarm (Optional)

OPERATING THE MACHINE

Control Lever (ISO Pattern) (Standard)

Control Lever (Hitachi Pattern)

Pilot Control Shut-off Lever

Steering Wheel Column

Warming-up Operation

Engine Speed Control

Auto-idle

Work Mode

Power Digging (Only ZAXIS210W-3)

Power Mode

Parking/Stopping the Machine on a Slope (In Case of Emergency)

Raising the Machine Front Above the Ground with the Boom and Arm Function

Excavation

Face Shovel Operation

Grading Operation

Do Not Slam the Bucket Teeth into the Ground

Do Not Use the Bucket as a Hammer

Avoid Increasing Digging Force Forcibly

Avoid Using Swing Power

Boom Lowering Procedure in Emergency or when the Engine Stalls

Overnight Storage Instructions

TRANSPORTING

Transporting by Road

Loading/Unloading on a Trailer

Transporting

Unloading

Towing Machine

12. Operators Manual (EMCGB-1-2)

Format: PDF, 369 pages

Language: English

Table of Contents:

INTRODUCTION

INDEX

MACHINE NUMBERS

SAFETY

SAFETY SIGNS

COMPONENTS NAME

OPERATORS STATION

BREAK-IN

OPERATING THE ENGINE

DRIVING THE MACHINE

OPERATING THE MACHINE

TRANSPORTING

MAINTENANCE

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

OPTIONAL ATTACHMENTS AND DEVICES

INDEX

13. Wiring Diagram (TTCGB-E-00-circuit2)

Format: PDF, 14 pages

Language: English

Table of Contents:

ZAXIS170W-3/190W-3 FRONT ATTACHMENT HARNESS (OPTIONAL)

ZAXIS170W-3/190W-3 FLOW RATE SELECTOR HARNESS (OPTIONAL)

ZAXIS140W-3/170W-3/190W-3 SELECTOR VALVE / SECONDARY PILOT RELIEF SELECTOR HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 BOOM BOTTOM PRESSURE SENSOR HARNESS (OPTIONAL)

ZAXIS170W-3/190W-3 ASSIST HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 FLOW RATE ADJUSTMENT ASSIST HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 ASSIST HARNESS (1) (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 ASSIST HARNESS (2) (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 OVERLOAD ALARM HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 OVERLOAD ALARM SUB HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3GRIP EXTENSION HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3GRIP EXTENSION HARNESS (FNR)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 HEATER SEAT HARNESS (OPTIONAL)

ZX140W-3/170W-3/190W-3/210W-3/220W-3 AUTO-CRUISE HARNESS (OPTIONAL)

14. Wiring Diagram (TTCGB-E-00-circuit)

Format: PDF, 20 pages

Language: English

Table of Contents:

ELECTRICAL CIRCUIT DIAGRAM (STANDARD)

ELECTRICAL CIRCUIT DIAGRAM (OPTIONAL)

CONNECTORS

CAB HARNESS

ENGINE HARNESS

FLOOR HARNESS

MONITOR HARNESS

CHASSIS HARNESS

LEFT CONSOLE HARNESS

AUXILIARY / POSITIONING SELECT HARNESS

BLADE / OUTRIGGER HARNESS

LICENSE PLATE HARNESS

POSITIONING HARNESS

PRESSURE SENSOR (POSITIONING) HARNESS

SWING PARKING BRAKE RELEASE HARNESS

HYDRAULIC CIRCUIT DIAGRAM (2-PIECE BOOM, FULLY OPTIONAL)

HYDRAULIC CIRCUIT DIAGRAM (MONOBLOCK BOOM, FULLY OPTIONAL)

15. Aditional Service Information (ZX170W-3_add)

Language: English

| Included in the package | |

| Workshop Manual | 1 |

| Troubleshooting Manual | 2 |

| Perfomance Check and Troubleshooting Manual | 1 |

| Engine Technical Manual | 2 |

| Maintenance Manual | 1 |

| Operational Principle Manual | 3 |

| Operators Manual | 2 |

| Wiring Diagram | 2 |

| Aditional Service Information | 1 |

| Covered | |

| Model Class | ZAXIS 170, ZAXIS 190 |

| Generation | 3 |

| Truck Type | Wheel Excavator |

| Truck Models | ZAXIS 170W-3, ZAXIS 190W-3 |

Hitachi Zaxis 170W-3 and Zaxis 190W-3 Wheel Excavator set of Service Manuals

- Brands Hitachi

- Product Code:Hitachi::ZX170W-3

- Availability:Ready to instant download

-

$23.00

Tags: Zaxis 170W-3, Zaxis 190W-3