All-Inclusive Factory Service Technical manual for Hitachi Crawler Excavators Models Zaxis 300LC-7 and Zaxis 300LCN-7.

This manuals will assist you in diagnosing, repairing, troubleshooting, and operating for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 300LC-7

Zaxis 300LCN-7

The manual comprises 6 documents, including the Workshop Manual, Troubleshooting Manual, Operational Principle Manual, Operators Manual, and two Wiring Diagrams

1. Workshop Manual (WDD650-EN-00)

Format: PDF, 770 pages

Language: English

Table of Contents:

GENERAL

Precautions for Disassembling and Assembling

Tightening

Painting

Bleeding Air

Preparation

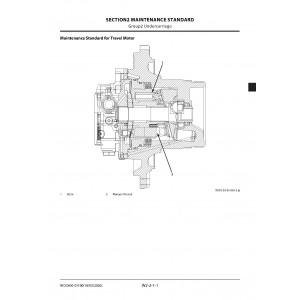

MAINTENANCE STANDARD

Upperstructure

Undercarriage

Front Attachment

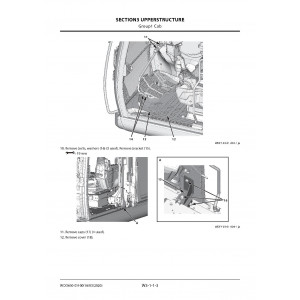

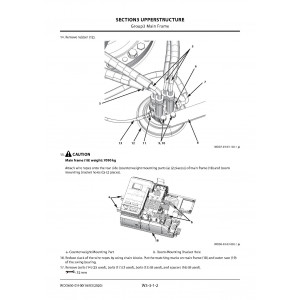

UPPERSTRUCTURE

Cab

Counterweight

Main Frame

Engine

Radiator Assembly

UPPERSTRUCTURE

Hydraulic Oil Tank

Fuel Tank

Pump Device

Control Valve

Swing Device

Pilot Valve

2. Troubleshooting Manual (TTDD650-EN-00)

Format: PDF, 706 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Machine Performance Test

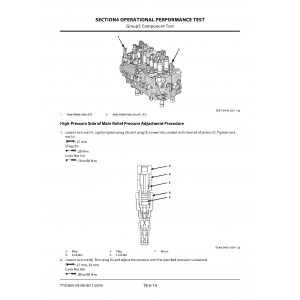

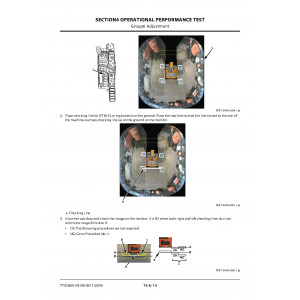

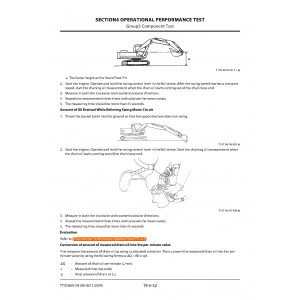

Component Test

Adjustment

TROUBLESHOOTING

Diagnosing Procedure

Monitor

e-Service

Component Layout

Troubleshooting A

Troubleshooting B

Air Conditioner

SERVICE MANUAL REVISION REQUEST FORM

The Attached Diagram List

3. Operational Principle Manual (TODD650-EN-00)

Format: PDF, 481 pages

Language: English

Table of Contents:

GENERAL

Specifications

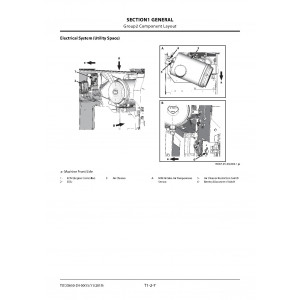

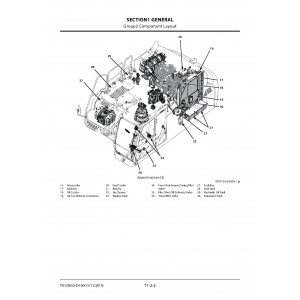

Component Layout

Component Specifications

SYSTEM

Controller

Control System

Engine System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

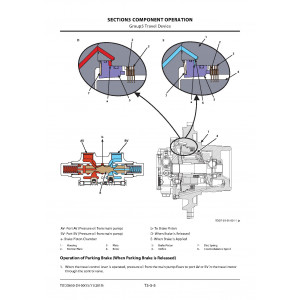

Travel Device

Signal Control Valve

Others (Upperstructure)

Others (Undercarriage)

4. Operators Manual (ENMDFY-EN1-1)

Format: PDF, 125 pages

Language: English

Table of Contents:

BEFORE OPERATION

Name of Components

Getting ON and OFF the Machine

About Aftertreatment Device

OPERATOR'S STATION

Layout of Equipment in Operator's Station (Illustration Contents)

Multi Function Monitor

Auto Air Conditioner

Audio Operation

Switch Panel (Illustration Content)

Switch Panel (for Optional Equipments)

Control Lever

Facilities in Operator's Station

Aerial Angle

Installation and Adjustment of Mirrors

Emergency Exit

Battery Disconnect Switch

BREAK-IN

Observe Engine Operation Closely

Every 8 Hours or Daily

After the First 50 Hours

After the First 100 Hours

OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Before Starting the Engine

Starting the Engine

Check Instruments After Starting

Using the Booster Battery

Stopping the Engine

Engine Auto-Stop at Extremely Low Temperatures

DRIVING THE MACHINE

Travel Levers and Pedals

Travel Mode Switch

Traveling on Soft Ground

Raising One Track Using the Boom and Arm

Retrieval

Operating in Water or Mud

Parking the Machine on Slopes

Parking

Prohibition of Sudden Control Operations when Traveling at High Speed

Prohibition of Traveling for Long Periods

OPERATING THE MACHINE

Control Lever (ISO Pattern)

Pilot Shut-Off Lever

Warming-Up Operation

Engine Speed Control

Auto-Idle

Auto Shut-Down

Aftertreatment Device Manual Regeneration

Attachments

Power Boost Switch

Power Mode

Attachment Settings

Operating Backhoe

Shovel

Grading Operation

Do Not Strike the Ground with Bucket Teeth

Avoid Hammer Work

Avoid Abusive Operation

Never Move an Object Sideways with the Bucket

Retracting the Arm and Bucket

Never use Wide Track Shoes on Rough Ground

Shackle Hole Usage

Pilot Accumulator Functions

How to Lower Boom in Case of Emergency and When Engine Stops (Without hose-rupture safety valve)

How to Lower Front Equipment and Attachment in Case of Emergency and When Engine Stops (With hose-rupture safety valve)

Precautions for After Operations

TRANSPORTING

Transporting by Road

Loading/Unloading on a Trailer

Fastening the Machine for Transport

Unloading

Lifting the Machine

MAINTENANCE

Correct Maintenance and Inspection Procedures

Layout

Inspection and Maintenance Intervals

Preparation for Inspection and Maintenance

Hood and Access Covers

Maintenance Guide

Periodic Replacement of Parts

Kind of Oils

List of Consumable Parts

A. Greasing

Electric Grease Gun (Only ZX330-7 Class)

Using the Electric Grease Gun

B. Engine

C. Transmission

D. Hydraulic System

E. Fuel System

F. Air Cleaner

G. Cooling System

H. Electrical System

I. Miscellaneous

J. Aftertreatment Device

K. Urea SCR System

L. Aerial Angle

HYDRAULIC CIRCUIT

Hydraulic Circuit

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

Storing the Machine

TROUBLESHOOTING

SPECIFICATIONS

Specifications ZX250LC-7, 250LCN-7

Working Ranges ZX250LC-7, 250LCN-7

Shoe Types and Applications ZX250LC-7

Shoe Types and Applications ZX250LCN-7

Bucket Types and Applications ZX250LC-7, 250LCN-7

Specifications ZX300LC-7, 300LCN-7

Working Ranges ZX300LC-7, 300LCN-7

Shoe Types and Applications ZX300LC-7

Shoe Types and Applications ZX300LCN-7

Bucket Types and Applications ZX300LC-7, 300LCN-7

Specifications ZX350LC-7, 350LCN-7

Working Ranges ZX350LC-7, 350LCN-7

Shoe Types and Applications ZX350LC-7

Shoe Types and Applications ZX350LCN-7

Bucket Types and Applications ZX350LC-7, 350LCN-7

The Value of the Carbon Dioxide (CO2) emissions

OPTIONAL ATTACHMENTS AND DEVICES

Link with Hook

Bucket Teeth (Transverse-Type-Pin-Used Type)

Replacement Procedure

2-Piece Boom

Attachment Pedal

Hydraulic Breaker, Crusher, Quick Hitch

INDEX

Blank Page

5. Wiring Diagram (TTDD650-EN-00_circuit)

Format: PDF, 17 pages

Language: English

Table of Contents:

ELECTRICAL CIRCUIT DIAGRAM

CONNECTORS

CAB HARNESS

MAN HARNESS

PUMP HARNESS

NOx HARNESS

MONITOR HARNESS

CONSOLE HARNESS

CONTROL VALVE HARNESS

WIPER HARNESS

WIPER MOTOR HARNESS

PILOT SHUT-OFF SOLENOID VALVE HARNESS

ENGINE STOP SWITCH HARNESS

CIGAR LIGHTER SUB HARNESS

HYDRAULIC CIRCUIT DIAGRAM (MONO BOOM)

HYDRAULIC CIRCUIT DIAGRAM (OPTION) (2-PIECE BOOM, AFL 1ch)

HYDRAULIC CIRCUIT DIAGRAM (OPTION) (2-PIECE BOOM, AFL 2ch)

6. Wiring Diagram (TTDD650-EN-00CIR)

Format: PDF, 13 pages

Language: English

Table of Contents:

ELECTRICAL CIRCUIT DIAGRAM (OPTION)

CONSOLE HARNESS (OPTION)

CAB REAR HARNESS

REAR HEADLIGHT HARNESS

REAR HEADLIGHT SWITCH HARNESS

REAR HEADLIGHT SUB HARNESS

HEADLIGHT HARNESS

AFL HARNESS (REAR SIDE) (1ch and 2ch)

AFL MAIN HARNESS (1ch)

AFL MAIN HARNESS (2ch)

CAMERA LIGHT HARNESS

BOOM LIGHT (RIGHT) HARNESS

AUXILIARY FLOW COMBINER HARNESS

This manuals will assist you in diagnosing, repairing, troubleshooting, and operating for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 300LC-7

Zaxis 300LCN-7

The manual comprises 6 documents, including the Workshop Manual, Troubleshooting Manual, Operational Principle Manual, Operators Manual, and two Wiring Diagrams

1. Workshop Manual (WDD650-EN-00)

Format: PDF, 770 pages

Language: English

Table of Contents:

GENERAL

Precautions for Disassembling and Assembling

Tightening

Painting

Bleeding Air

Preparation

MAINTENANCE STANDARD

Upperstructure

Undercarriage

Front Attachment

UPPERSTRUCTURE

Cab

Counterweight

Main Frame

Engine

Radiator Assembly

UPPERSTRUCTURE

Hydraulic Oil Tank

Fuel Tank

Pump Device

Control Valve

Swing Device

Pilot Valve

2. Troubleshooting Manual (TTDD650-EN-00)

Format: PDF, 706 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Machine Performance Test

Component Test

Adjustment

TROUBLESHOOTING

Diagnosing Procedure

Monitor

e-Service

Component Layout

Troubleshooting A

Troubleshooting B

Air Conditioner

SERVICE MANUAL REVISION REQUEST FORM

The Attached Diagram List

3. Operational Principle Manual (TODD650-EN-00)

Format: PDF, 481 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

Component Specifications

SYSTEM

Controller

Control System

Engine System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Travel Device

Signal Control Valve

Others (Upperstructure)

Others (Undercarriage)

4. Operators Manual (ENMDFY-EN1-1)

Format: PDF, 125 pages

Language: English

Table of Contents:

BEFORE OPERATION

Name of Components

Getting ON and OFF the Machine

About Aftertreatment Device

OPERATOR'S STATION

Layout of Equipment in Operator's Station (Illustration Contents)

Multi Function Monitor

Auto Air Conditioner

Audio Operation

Switch Panel (Illustration Content)

Switch Panel (for Optional Equipments)

Control Lever

Facilities in Operator's Station

Aerial Angle

Installation and Adjustment of Mirrors

Emergency Exit

Battery Disconnect Switch

BREAK-IN

Observe Engine Operation Closely

Every 8 Hours or Daily

After the First 50 Hours

After the First 100 Hours

OPERATING THE ENGINE

Inspect Machine Daily Before Starting

Before Starting the Engine

Starting the Engine

Check Instruments After Starting

Using the Booster Battery

Stopping the Engine

Engine Auto-Stop at Extremely Low Temperatures

DRIVING THE MACHINE

Travel Levers and Pedals

Travel Mode Switch

Traveling on Soft Ground

Raising One Track Using the Boom and Arm

Retrieval

Operating in Water or Mud

Parking the Machine on Slopes

Parking

Prohibition of Sudden Control Operations when Traveling at High Speed

Prohibition of Traveling for Long Periods

OPERATING THE MACHINE

Control Lever (ISO Pattern)

Pilot Shut-Off Lever

Warming-Up Operation

Engine Speed Control

Auto-Idle

Auto Shut-Down

Aftertreatment Device Manual Regeneration

Attachments

Power Boost Switch

Power Mode

Attachment Settings

Operating Backhoe

Shovel

Grading Operation

Do Not Strike the Ground with Bucket Teeth

Avoid Hammer Work

Avoid Abusive Operation

Never Move an Object Sideways with the Bucket

Retracting the Arm and Bucket

Never use Wide Track Shoes on Rough Ground

Shackle Hole Usage

Pilot Accumulator Functions

How to Lower Boom in Case of Emergency and When Engine Stops (Without hose-rupture safety valve)

How to Lower Front Equipment and Attachment in Case of Emergency and When Engine Stops (With hose-rupture safety valve)

Precautions for After Operations

TRANSPORTING

Transporting by Road

Loading/Unloading on a Trailer

Fastening the Machine for Transport

Unloading

Lifting the Machine

MAINTENANCE

Correct Maintenance and Inspection Procedures

Layout

Inspection and Maintenance Intervals

Preparation for Inspection and Maintenance

Hood and Access Covers

Maintenance Guide

Periodic Replacement of Parts

Kind of Oils

List of Consumable Parts

A. Greasing

Electric Grease Gun (Only ZX330-7 Class)

Using the Electric Grease Gun

B. Engine

C. Transmission

D. Hydraulic System

E. Fuel System

F. Air Cleaner

G. Cooling System

H. Electrical System

I. Miscellaneous

J. Aftertreatment Device

K. Urea SCR System

L. Aerial Angle

HYDRAULIC CIRCUIT

Hydraulic Circuit

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

Storing the Machine

TROUBLESHOOTING

SPECIFICATIONS

Specifications ZX250LC-7, 250LCN-7

Working Ranges ZX250LC-7, 250LCN-7

Shoe Types and Applications ZX250LC-7

Shoe Types and Applications ZX250LCN-7

Bucket Types and Applications ZX250LC-7, 250LCN-7

Specifications ZX300LC-7, 300LCN-7

Working Ranges ZX300LC-7, 300LCN-7

Shoe Types and Applications ZX300LC-7

Shoe Types and Applications ZX300LCN-7

Bucket Types and Applications ZX300LC-7, 300LCN-7

Specifications ZX350LC-7, 350LCN-7

Working Ranges ZX350LC-7, 350LCN-7

Shoe Types and Applications ZX350LC-7

Shoe Types and Applications ZX350LCN-7

Bucket Types and Applications ZX350LC-7, 350LCN-7

The Value of the Carbon Dioxide (CO2) emissions

OPTIONAL ATTACHMENTS AND DEVICES

Link with Hook

Bucket Teeth (Transverse-Type-Pin-Used Type)

Replacement Procedure

2-Piece Boom

Attachment Pedal

Hydraulic Breaker, Crusher, Quick Hitch

INDEX

Blank Page

5. Wiring Diagram (TTDD650-EN-00_circuit)

Format: PDF, 17 pages

Language: English

Table of Contents:

ELECTRICAL CIRCUIT DIAGRAM

CONNECTORS

CAB HARNESS

MAN HARNESS

PUMP HARNESS

NOx HARNESS

MONITOR HARNESS

CONSOLE HARNESS

CONTROL VALVE HARNESS

WIPER HARNESS

WIPER MOTOR HARNESS

PILOT SHUT-OFF SOLENOID VALVE HARNESS

ENGINE STOP SWITCH HARNESS

CIGAR LIGHTER SUB HARNESS

HYDRAULIC CIRCUIT DIAGRAM (MONO BOOM)

HYDRAULIC CIRCUIT DIAGRAM (OPTION) (2-PIECE BOOM, AFL 1ch)

HYDRAULIC CIRCUIT DIAGRAM (OPTION) (2-PIECE BOOM, AFL 2ch)

6. Wiring Diagram (TTDD650-EN-00CIR)

Format: PDF, 13 pages

Language: English

Table of Contents:

ELECTRICAL CIRCUIT DIAGRAM (OPTION)

CONSOLE HARNESS (OPTION)

CAB REAR HARNESS

REAR HEADLIGHT HARNESS

REAR HEADLIGHT SWITCH HARNESS

REAR HEADLIGHT SUB HARNESS

HEADLIGHT HARNESS

AFL HARNESS (REAR SIDE) (1ch and 2ch)

AFL MAIN HARNESS (1ch)

AFL MAIN HARNESS (2ch)

CAMERA LIGHT HARNESS

BOOM LIGHT (RIGHT) HARNESS

AUXILIARY FLOW COMBINER HARNESS

| Included in the package | |

| Workshop Manual | 1 |

| Troubleshooting Manual | 1 |

| Operational Principle Manual | 1 |

| Operators Manual | 1 |

| Wiring Diagram | 2 |

| Covered | |

| Model Class | ZAXIS 300 |

| Generation | 7 |

| Truck Type | Crawler Excavator |

| Truck Models | ZAXIS 300LC-7, ZAXIS 300LCN-7 |

Hitachi Zaxis 300LC-7 and Zaxis 300LCN-7 Crawler Excavator set of Service Manuals

- Brands Hitachi

- Product Code:Hitachi::ZX300LC-7

- Availability:Ready to instant download

-

$23.00

Tags: Zaxis 300LC-7, Zaxis 300LCN-7