All-Inclusive Factory Service Technical manual for Hitachi Hydraulic Excavators Models EX1200-5D.

This manuals will assist you in diagnosing, repairing, troubleshooting, maintaining, operating, assembling, and checking for your hydraulic excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

EX1200-5D

The manual comprises 19 documents, including five Workshop Manuals, the Troubleshooting Manual, Maintenance Manual, Operational Principle Manual, Operators Manual, Wiring Diagram, Assembly Manual, and 8 Check Sheets

1. Workshop Manual: Main Pump (WSDMPDE17F2)

Format: PDF, 152 pages

Language: English

2. Workshop Manual (W18FE00)

Format: PDF, 469 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Precautions for Disassembling and Assembling

Tightening

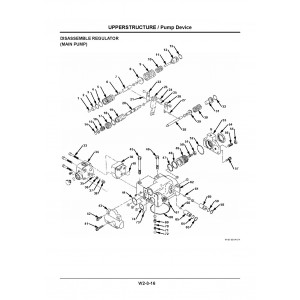

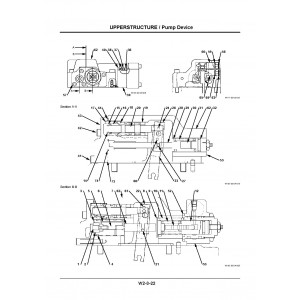

UPPERSTRUCTURE

Cab

Counterweight

Pump Device

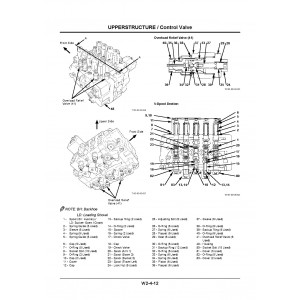

Control Valve

Swing Device

Pilot Valve

Pilot Shut-off Valve

Shockless Valve

Solenoid Valve

Signal Control Valve

Oil Cooler Fan Motor

UNDERCARRIAGE

Swing Bearing

Travel Device

Center Joint

Track Adjuster

Front Idler

Upper And Lower Roller

Track

FRONT ATTACHMENT

Front Attachment

Cylinder

Bushing and Point

3. Workshop Manual: Pump Transmission (WSDPDE17F1)

Format: PDF, 122 pages

Language: English

4. Workshop Manual: Travel Transmission (WSDTDE17F1)

Format: PDF, 166 pages

Language: English

5. Workshop Manual: Swing Motor (WSDSME17F2)

Format: PDF, 146 pages

Language: English

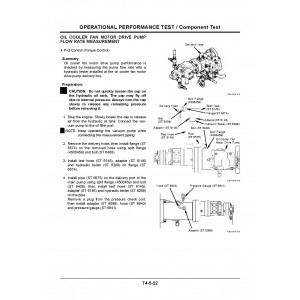

6. Troubleshooting Manual (TT18FE01)

Format: PDF, 370 pages

Language: English

Table of Contents:

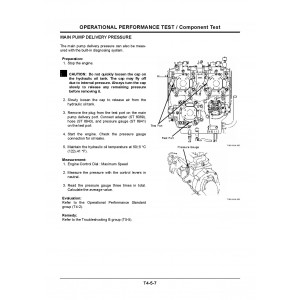

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Component Test

TROUBLESHOOTING

General

Cross Reference Table

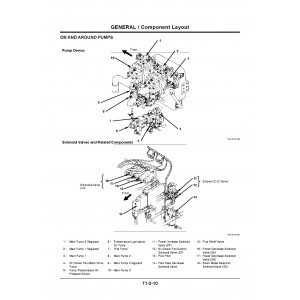

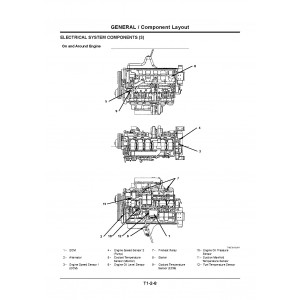

Component Layout

Troubleshooting A

Troubleshooting B

Troubleshooting C

Troubleshooting D

Electrical System Inspection

7. Maintenance Manual: Recomended Service Program (KO27600)

Format: PDF, 42 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

MAJOR COMPONENTS PREVENTIVE SERVICE SCHEDULE

HITACHE SCHEDULED DIAGNOSTIC SERVICE

CHECK LISTS FOR PERFORMANCE AND COMPONENTS

RECOMMENDATION OF PREVENTIVE SERVICE TO CUSTOMER

RECOMMENDED PARTS CATALOG FOR PREVENTIVE SERVICE

8. Operational Principle Manual (TO18FE01)

Format: PDF, 244 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

SYSTEM

Control System

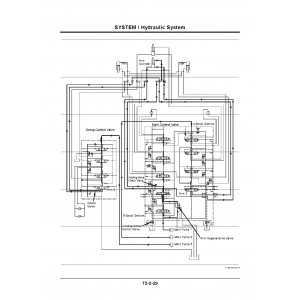

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Travel Device

Signal Control Valve

Other (Upperstructure)

Other (Undercarriage)

9. Operators Manual (EM18FEN11)

Format: PDF, 305 pages

Language: English

Table of Contents:

INTRODUCTION

INDEX

MACHINE NUMBERS

SAFETY

SAFETY SIGNS

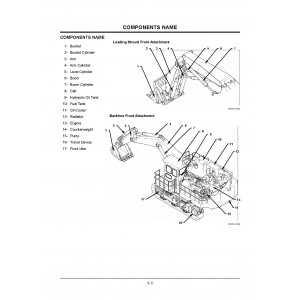

COMPONENTS NAME

GETTING ON / OFF THE MACHINE

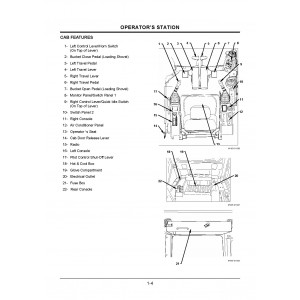

OPERATORS STATION

BREAK-IN

OPERATING THE ENGINE

DRIVING THE MACHINE

OPERATING THE MACHINE

TRANSPORTING

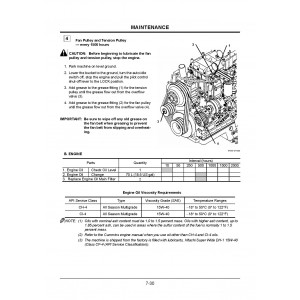

MAINTENANCE

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

INDEX

10. Wiring Diagram (TT18FE01CIR)

Format: PDF, 6 pages

Language: English

Table of Contents:

EX1200-5D ELECTRICAL CIRCUIT DIAGRAM

EX1200-5D CONNECTORS

EX1200-5D HYDRAULIC CIRCUIT DIAGRAM (BACKHOE)

EX1200-5D HYDRAULIC CIRCUIT DIAGRAM (LOADING SHOVEL)

11. Assembly Manual (KO26900_POD)

Format: PDF, 192 pages

Language: English

Table of Contents:

COVER

Foreword

1. Precautions

2. Workers plan (Loader front)

2'. Workers plan (Backhoe front)

3. Parts check

4. Preparations (Loader front)

5. Preparations (Backhoe front)

6. Machines, apparatus, tools, and materials necessary for assembly

ASSEMBLY OF UPPERSTRUCTURE

MOUNTING PROCEDURE FOR LOADER FRONT-END ATTACHMENT

MOUNTING PROCEDURE FOR BACKHOE FRONT-END ATTACHMENT

CHECKS & PERFORMANCE STANDARDS

10. Check after completing of assembly

11. Checking machine performance

BACK COVER

12. Check Sheets: UT Inspection (Backhoe Front) (KO274BE00)

Format: PDF, 52 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

DISTRIBUTION OF THE INSPECTION SHEET

DEFINITION OF THE DEFECT LENGTH IN ULTRA-SONIC

INSPECTION PROCEDURE

EVALUATION OF DEFECT HEIGHT (H)BY DISTANCE CORRECTION TECHNIQUE AT INTERNAL BULKHEAD

ULTRA-SONIC EXAMINATION REPORT FOR THE STRUCTURE

Track Frame

Loader Boom

Loader Arm

13. Check Sheets: Monthly Maintenance (KO27200)

Format: PDF, 55 pages

Language: English

Table of Contents:

COVER

1. 50 TO 1250 HOURS

2. 1500 TO 2500 HOURS

3. 2750 TO 3750 HOURS

4. 4000 TO 5000 HOURS

5. 5250 TO 6250 HOURS

6. 6500 TO 7500 HOURS

7. 7750 TO 8750 HOURS

8. 9000 TO 10000 HOURS

9. 10250 TO 11250 HOURS

10. 11500 TO 12500 HOURS

11. 12750 TO 13750 HOURS

12. 14000 TO 15000 HOURS

13. 15250 TO 16250 HOURS

14. 16500 TO 17500 HOURS

15. 17750 TO 18750 HOURS

16. 19000 TO 20000 HOURS

14. Check Sheets: Daily and Weekly Maintenance (KO27100)

Format: PDF, 5 pages

Language: English

15. Check Sheets: Completed Assembly (KO27000)

Format: PDF, 25 pages

Language: English

Table of Contents:

COVER

FOREWORD

COMPLETED ASSEMBLY CHECK REPORT FOR THE EX1200-5

UNDERCARRIAGE/SUPERSTRUCTURE

FRONT-END ATTACHEMNT

ELECTRICAL SYSTEM FUNCTION CHECK SHEETS

IMPLEMENT SPEED CHECK SHEETS

16. Check Sheets: Visual Inspection (Loader Front) (KO275L00)

Format: PDF, 38 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

COMPLETING AND SUBMITTING THE INSPECTION SHEETS

INSPECTION PROCEDURE

STRUCTURE VISUAL INSPECTION CHECK REPORT

Track Frame

Side Frame

Main Frame

Loader Boom

Loader Arm

17. Check Sheets: Visual Inspection (Bachkhoe Front) (KO275BE00)

Format: PDF, 40 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

COMPLETING AND SUBMITTING THE INSPECTION SHEETS

INSPECTION PROCEDURE

STRUCTURE VISUAL INSPECTION CHECK REPORT

Track Frame

Side Frame

Main Frame

Backhoe BE Boom

Backhoe Arm

18. Check Sheets: UT Inspection (Loader Front) (ko274l00)

Format: PDF, 58 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

DISTRIBUTION OF THE INSPECTION SHEET

DEFINITION OF THE DEFECT LENGTH IN ULTRA-SONIC TESTING

INSPECTION PROCEDURE

EVALUATION OF DEFECT HEIGHT(H)BY DISTANCE CORRECTION TECHNIQUE AT INTERNAL BULKHEAD

ULTRA-SONIC EXAMINATION REPORT FOR THE STRUCTURE

Track Frame

Loader Boom

Loader Arm

19. Check Sheets: Parts Visual Check (ko27300)

Format: PDF, 41 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

INSPECTION PROCEDURE

PRECAUTIONS FOR INSPECTION

PRECAUTIONS IN USING THE PARTS VISUAL CHECK SHEET

PIPING SYSTEM

ELECTRIC PARTS

IMPORTANT CHECKS

This manuals will assist you in diagnosing, repairing, troubleshooting, maintaining, operating, assembling, and checking for your hydraulic excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

EX1200-5D

The manual comprises 19 documents, including five Workshop Manuals, the Troubleshooting Manual, Maintenance Manual, Operational Principle Manual, Operators Manual, Wiring Diagram, Assembly Manual, and 8 Check Sheets

1. Workshop Manual: Main Pump (WSDMPDE17F2)

Format: PDF, 152 pages

Language: English

2. Workshop Manual (W18FE00)

Format: PDF, 469 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Precautions for Disassembling and Assembling

Tightening

UPPERSTRUCTURE

Cab

Counterweight

Pump Device

Control Valve

Swing Device

Pilot Valve

Pilot Shut-off Valve

Shockless Valve

Solenoid Valve

Signal Control Valve

Oil Cooler Fan Motor

UNDERCARRIAGE

Swing Bearing

Travel Device

Center Joint

Track Adjuster

Front Idler

Upper And Lower Roller

Track

FRONT ATTACHMENT

Front Attachment

Cylinder

Bushing and Point

3. Workshop Manual: Pump Transmission (WSDPDE17F1)

Format: PDF, 122 pages

Language: English

4. Workshop Manual: Travel Transmission (WSDTDE17F1)

Format: PDF, 166 pages

Language: English

5. Workshop Manual: Swing Motor (WSDSME17F2)

Format: PDF, 146 pages

Language: English

6. Troubleshooting Manual (TT18FE01)

Format: PDF, 370 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Component Test

TROUBLESHOOTING

General

Cross Reference Table

Component Layout

Troubleshooting A

Troubleshooting B

Troubleshooting C

Troubleshooting D

Electrical System Inspection

7. Maintenance Manual: Recomended Service Program (KO27600)

Format: PDF, 42 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

MAJOR COMPONENTS PREVENTIVE SERVICE SCHEDULE

HITACHE SCHEDULED DIAGNOSTIC SERVICE

CHECK LISTS FOR PERFORMANCE AND COMPONENTS

RECOMMENDATION OF PREVENTIVE SERVICE TO CUSTOMER

RECOMMENDED PARTS CATALOG FOR PREVENTIVE SERVICE

8. Operational Principle Manual (TO18FE01)

Format: PDF, 244 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

SYSTEM

Control System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Travel Device

Signal Control Valve

Other (Upperstructure)

Other (Undercarriage)

9. Operators Manual (EM18FEN11)

Format: PDF, 305 pages

Language: English

Table of Contents:

INTRODUCTION

INDEX

MACHINE NUMBERS

SAFETY

SAFETY SIGNS

COMPONENTS NAME

GETTING ON / OFF THE MACHINE

OPERATORS STATION

BREAK-IN

OPERATING THE ENGINE

DRIVING THE MACHINE

OPERATING THE MACHINE

TRANSPORTING

MAINTENANCE

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

TROUBLESHOOTING

SPECIFICATIONS

INDEX

10. Wiring Diagram (TT18FE01CIR)

Format: PDF, 6 pages

Language: English

Table of Contents:

EX1200-5D ELECTRICAL CIRCUIT DIAGRAM

EX1200-5D CONNECTORS

EX1200-5D HYDRAULIC CIRCUIT DIAGRAM (BACKHOE)

EX1200-5D HYDRAULIC CIRCUIT DIAGRAM (LOADING SHOVEL)

11. Assembly Manual (KO26900_POD)

Format: PDF, 192 pages

Language: English

Table of Contents:

COVER

Foreword

1. Precautions

2. Workers plan (Loader front)

2'. Workers plan (Backhoe front)

3. Parts check

4. Preparations (Loader front)

5. Preparations (Backhoe front)

6. Machines, apparatus, tools, and materials necessary for assembly

ASSEMBLY OF UPPERSTRUCTURE

MOUNTING PROCEDURE FOR LOADER FRONT-END ATTACHMENT

MOUNTING PROCEDURE FOR BACKHOE FRONT-END ATTACHMENT

CHECKS & PERFORMANCE STANDARDS

10. Check after completing of assembly

11. Checking machine performance

BACK COVER

12. Check Sheets: UT Inspection (Backhoe Front) (KO274BE00)

Format: PDF, 52 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

DISTRIBUTION OF THE INSPECTION SHEET

DEFINITION OF THE DEFECT LENGTH IN ULTRA-SONIC

INSPECTION PROCEDURE

EVALUATION OF DEFECT HEIGHT (H)BY DISTANCE CORRECTION TECHNIQUE AT INTERNAL BULKHEAD

ULTRA-SONIC EXAMINATION REPORT FOR THE STRUCTURE

Track Frame

Loader Boom

Loader Arm

13. Check Sheets: Monthly Maintenance (KO27200)

Format: PDF, 55 pages

Language: English

Table of Contents:

COVER

1. 50 TO 1250 HOURS

2. 1500 TO 2500 HOURS

3. 2750 TO 3750 HOURS

4. 4000 TO 5000 HOURS

5. 5250 TO 6250 HOURS

6. 6500 TO 7500 HOURS

7. 7750 TO 8750 HOURS

8. 9000 TO 10000 HOURS

9. 10250 TO 11250 HOURS

10. 11500 TO 12500 HOURS

11. 12750 TO 13750 HOURS

12. 14000 TO 15000 HOURS

13. 15250 TO 16250 HOURS

14. 16500 TO 17500 HOURS

15. 17750 TO 18750 HOURS

16. 19000 TO 20000 HOURS

14. Check Sheets: Daily and Weekly Maintenance (KO27100)

Format: PDF, 5 pages

Language: English

15. Check Sheets: Completed Assembly (KO27000)

Format: PDF, 25 pages

Language: English

Table of Contents:

COVER

FOREWORD

COMPLETED ASSEMBLY CHECK REPORT FOR THE EX1200-5

UNDERCARRIAGE/SUPERSTRUCTURE

FRONT-END ATTACHEMNT

ELECTRICAL SYSTEM FUNCTION CHECK SHEETS

IMPLEMENT SPEED CHECK SHEETS

16. Check Sheets: Visual Inspection (Loader Front) (KO275L00)

Format: PDF, 38 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

COMPLETING AND SUBMITTING THE INSPECTION SHEETS

INSPECTION PROCEDURE

STRUCTURE VISUAL INSPECTION CHECK REPORT

Track Frame

Side Frame

Main Frame

Loader Boom

Loader Arm

17. Check Sheets: Visual Inspection (Bachkhoe Front) (KO275BE00)

Format: PDF, 40 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

COMPLETING AND SUBMITTING THE INSPECTION SHEETS

INSPECTION PROCEDURE

STRUCTURE VISUAL INSPECTION CHECK REPORT

Track Frame

Side Frame

Main Frame

Backhoe BE Boom

Backhoe Arm

18. Check Sheets: UT Inspection (Loader Front) (ko274l00)

Format: PDF, 58 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

DISTRIBUTION OF THE INSPECTION SHEET

DEFINITION OF THE DEFECT LENGTH IN ULTRA-SONIC TESTING

INSPECTION PROCEDURE

EVALUATION OF DEFECT HEIGHT(H)BY DISTANCE CORRECTION TECHNIQUE AT INTERNAL BULKHEAD

ULTRA-SONIC EXAMINATION REPORT FOR THE STRUCTURE

Track Frame

Loader Boom

Loader Arm

19. Check Sheets: Parts Visual Check (ko27300)

Format: PDF, 41 pages

Language: English

Table of Contents:

COVER

INTRODUCTION

INSPECTION PROCEDURE

PRECAUTIONS FOR INSPECTION

PRECAUTIONS IN USING THE PARTS VISUAL CHECK SHEET

PIPING SYSTEM

ELECTRIC PARTS

IMPORTANT CHECKS

| Included in the package | |

| Workshop Manual | 5 |

| Troubleshooting Manual | 1 |

| Maintenance Manual | 1 |

| Operational Principle Manual | 1 |

| Operators Manual | 1 |

| Wiring Diagram | 1 |

| Assembly Manual | 1 |

| Check Sheets | 8 |

| Covered | |

| Model Class | EX1200 |

| Generation | 5D |

| Truck Type | Hydraulic Excavator |

| Truck Models | EX1200-5D |

Hitachi EX1200-5D Hydraulic Excavator set of Service Manuals

- Brands Hitachi

- Product Code:Hitachi::EX1200-5D

- Availability:Ready to instant download

-

$49.90

Tags: EX1200-5D