All-Inclusive Factory Service Technical manual for Hitachi Hydraulic Excavators Models EX3600-6.

This manuals will assist you in diagnosing, repairing, troubleshooting, operating, assembling, and checking for your hydraulic excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

EX3600-6

The manual comprises 17 documents, including three Workshop Manuals, the Troubleshooting Manual, Operational Principle Manual, four Operators Manuals, Wiring Diagram, Assembly Manual, and 6 Check Sheets

1. Workshop Manual: Travel Transmission (WSDTDE188)

Format: PDF, 154 pages

Language: English

2. Workshop Manual: Travel Transmission (WSDTDE1882)

Format: PDF, 150 pages

Language: English

3. Workshop Manual (W18ME00)

Format: PDF, 526 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Precautions for Disassembling and Assembling

Tightening Torque

Painting

Bleeding Air from Hydraulic OilTank

UPPERSTRUCTURE

Cab

Counterweight

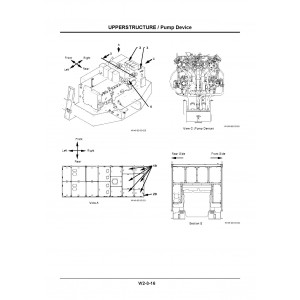

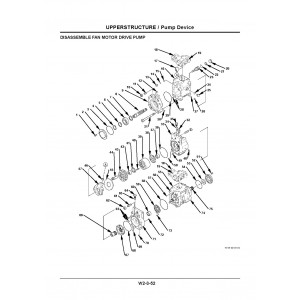

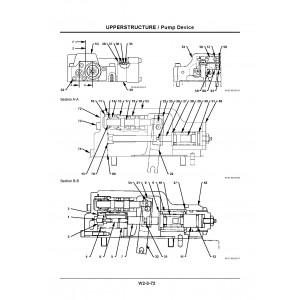

Pump Device

Control Valve

Swing Device

DQR Valve

Shuttle Valve

8-Spool Solenoid Valve

Oil Cooler Fan Motor

Radiator Fan Motor

Compressor Drive Motor

Air Conditioner

Lift Cylinder (Fast-Filling/Draining Device)

Lift Cylinder (Sliding Fold-In Ladder)

UNDERCARRIAGE

Swing Bearing

Travel Device

Travel Brake Valve

Drive Tumbler

Center Joint

Adjuster Cylinder

Front Idler

Upper and Lower Roller

Track

Accumulator

Welding Repair Procedure

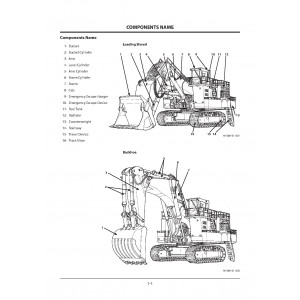

FRONT ATTACHMENT

Front Attachment

Cylinder

Bushing and Point

4. Troubleshooting Manual (TT18ME00)

Format: PDF, 250 pages

Language: English

Table of Contents:

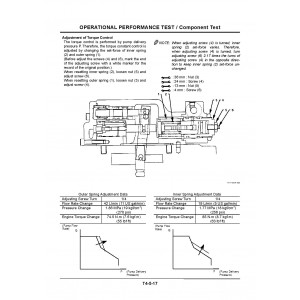

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Component Test

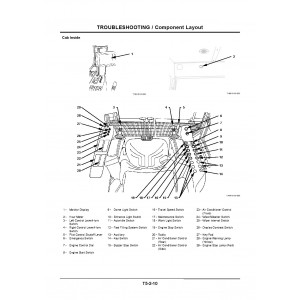

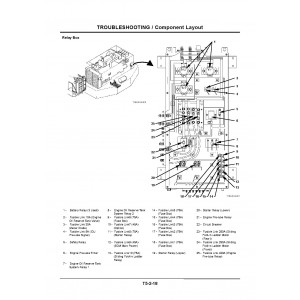

TROUBLESHOOTING

General

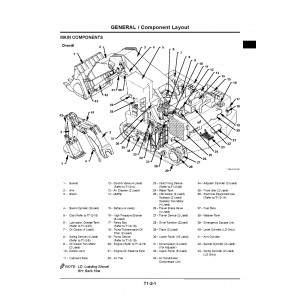

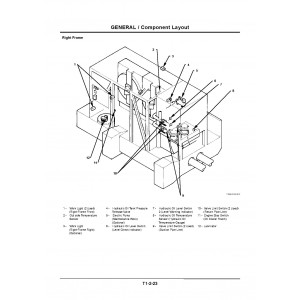

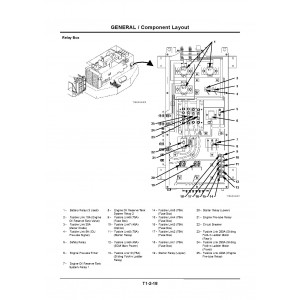

Component Layout

Troubleshooting A

Troubleshooting B

Troubleshooting C

Electrical System Inspection

5. Operational Principle Manual (TO18ME00)

Format: PDF, 270 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

Component Specifications

SYSTEM

Controller

Control System

ELU System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Control Equipment

D.Q.R Valve

Travel Device

Others (Upperstructure)

Others (Undercarriage)

6. Operators Manual (EM18M12)

Format: PDF, 308 pages

Language: English

7. Operators Manual: Quick Visual Inspection (Loader Front) (KO44502)

Format: PDF, 248 pages

Language: English

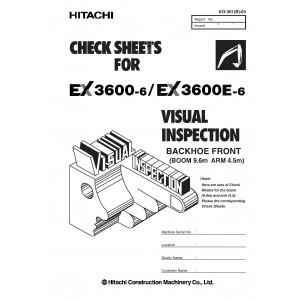

8. Operators Manual: Quick Visual Inspection (Backhoe Front) (KO41502)

Format: PDF, 248 pages

Language: English

9. Operators Manual (EM18M11)

Format: PDF, 307 pages

Language: English

10. Wiring Diagram (TT18ME00CIR)

Format: PDF, 11 pages

Language: English

Table of Contents:

EX1900-6,EX2600-6,EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (CAB)

EX1900-6(Up to serial No.1068), EX2500-6(Up to serial No.1087), EX3600-6(Up to serial No.1090) ELECTRICAL CIRCUIT DIAGRAM (ELECTRICAL EQUIPMENT BOX 1/2)

EX1900-6(Serial No.1069 and up), EX2500-6(Serial No.1088 and up), EX3600-6(Serial No.1091 and up) ELECTRICAL CIRCUIT DIAGRAM (ELECTRICAL EQUIPMENT BOX 1/2)

EX1900-6,EX2600-6,EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (ELECTRICAL EQUIPMENT BOX 2/2)

EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (MACHINE LEFT)

EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (MACHINE CENTER)

EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (MACHINE RIGHT)

EX1900-6,EX2600-6,EX3600-6 ELECTRIC CONNECTORS

EX3600-6 HYDRAULIC CIRCUIT DIAGRAM (BACKHOE)(Selial No.1001)

EX3600-6 HYDRAULIC CIRCUIT DIAGRAM (BACKHOE)(Serial No.1002 AND AFTER)

EX3600-6 HYDRAULIC CIRCUIT DIAGRAM (LOADING SHOVEL)

11. Assembly Manual (KO32601)

Format: PDF, 401 pages

Language: English

Table of Contents:

1. Precautions

1-1 Safety precautions for servicemen

1-2 How to use a power wrench

1-3 Work precautions

2. Workers plan

2'. Workers plan

2-1 Transportation of Loader Front

2-1' Transportation of Backhoe Front

3. Parts check

4. Preparations (loader front)

4'. Preparations (backhoe front)

5. Machines, apparatus, tools, and materials necessary for assembly

6. Assembly of undercarriage

6-1 Preparation

6-2 Connection of track frame and side frames

6-3 Connection of travel motor piping and adjuster piping

6-4 Assembly of motor covers and step

6-5 Disassembly procedures for shipment (Procedure, Track)

6-6 Assembly of travel motor guard and mission guard(option)

7. Connection of undercarriage and superstructure

7-1 Preparations before connection

7-2 Preparation of undercarriage

7-3 Preparation of main frame

7-4 Connection of undercarriage and main frame assembly

7-5 Connection of piping to center joint

7-6 Assembly of bed (left)

7-7 Assembly of bed (right)

7-8 Installation of bed (right)

7-9 Installation of bed (left)

7-10 Assembly of engine unit

7-11 Mounting of counterweight & reserve tank

7-12 Connecting of various sections

7-13 Checking of stop valves

7-14 Final check of superstructure

7-15 Releasing air from main pumps

7-16 Trial operation of superstructure

7-17 Disassembly procedures for shipment

7-18 Assembly of parts (option)

8. Mounting procedure for loader front-end attachment

8-1 Preparation

8-2 Mounting of boom

8-3 Installation of bucket cylinders

8-4 Mounting of arm

8-5 Mounting of bucket

8-6 Releasing air from the cylinders

8-7 Adjustment of track link tension

8-8 Final trial operation check

8-9 Disassembly procedures for shipment

8'. Mounting procedure for backhoe front-end attachment

8'-1 Preparation

8'-2 Mounting of boom

8'-3 Installation of arm

8'-4 Mounting of bucket

8'-5 Releasing air from the cylinders

8'-6 Adjustment of track link tension

8'-7 Final trial operation check

8'-8 Disassembly procedures for shipment

9. Checks after completing the assembly

10. Checking machine performance

12. Check Sheets: Visual Inspection (Backhoe Front) (KO361B03)

Format: PDF, 37 pages

Language: English

13. Check Sheets: Daily and Weekly Maintenance (KO33300)

Format: PDF, 4 pages

Language: English

14. Check Sheets: Monthly Maintenance (KO33400)

Format: PDF, 73 pages

Language: English

Table of Contents:

CHECK SHEETS FOR EX3600-6

1 50 HOURS to 1250 HOURS

2 1500 HOURS to 2500 HOURS

3 2750 HOURS to 3750 HOURS

4 4000 HOURS to 5000 HOURS

5 5250 HOURS to 6250 HOURS

6 6500 HOURS to 7500 HOURS

7 7750 HOURS to 8750 HOURS

8 9000 HOURS to 10000 HOURS

9 10250 HOURS to 11250 HOURS

10 11500 HOURS to 12500 HOURS

11 12750 HOURS to 13750 HOURS

12 14000 HOURS to 15000 HOURS

13 15250 HOURS to 16250 HOURS

14 16500 HOURS to 17500 HOURS

15 17750 HOURS to 18750 HOURS

16 19000 HOURS to 20000 HOURS

EX3600-6 CHECK POINTS : 1

EX3600-6 CHECK POINTS : 2

FOR EX3600-6 PERIODIC REPLACEMENT OF RUBBER HOSES

HOW TO USE THE EX3600-6 SHEETS

15. Check Sheets: UT Inspection (Backhoe Front) (KO38401)

Format: PDF, 64 pages

Language: English

16. Check Sheets: UT Inspection (Loader Front) (KO52601)

Format: PDF, 64 pages

Language: English

17. Check Sheets: Visual Inspection (Loader Front) (KO361L03)

Format: PDF, 39 pages

Language: English

This manuals will assist you in diagnosing, repairing, troubleshooting, operating, assembling, and checking for your hydraulic excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

EX3600-6

The manual comprises 17 documents, including three Workshop Manuals, the Troubleshooting Manual, Operational Principle Manual, four Operators Manuals, Wiring Diagram, Assembly Manual, and 6 Check Sheets

1. Workshop Manual: Travel Transmission (WSDTDE188)

Format: PDF, 154 pages

Language: English

2. Workshop Manual: Travel Transmission (WSDTDE1882)

Format: PDF, 150 pages

Language: English

3. Workshop Manual (W18ME00)

Format: PDF, 526 pages

Language: English

Table of Contents:

GENERAL INFORMATION

Precautions for Disassembling and Assembling

Tightening Torque

Painting

Bleeding Air from Hydraulic OilTank

UPPERSTRUCTURE

Cab

Counterweight

Pump Device

Control Valve

Swing Device

DQR Valve

Shuttle Valve

8-Spool Solenoid Valve

Oil Cooler Fan Motor

Radiator Fan Motor

Compressor Drive Motor

Air Conditioner

Lift Cylinder (Fast-Filling/Draining Device)

Lift Cylinder (Sliding Fold-In Ladder)

UNDERCARRIAGE

Swing Bearing

Travel Device

Travel Brake Valve

Drive Tumbler

Center Joint

Adjuster Cylinder

Front Idler

Upper and Lower Roller

Track

Accumulator

Welding Repair Procedure

FRONT ATTACHMENT

Front Attachment

Cylinder

Bushing and Point

4. Troubleshooting Manual (TT18ME00)

Format: PDF, 250 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Component Test

TROUBLESHOOTING

General

Component Layout

Troubleshooting A

Troubleshooting B

Troubleshooting C

Electrical System Inspection

5. Operational Principle Manual (TO18ME00)

Format: PDF, 270 pages

Language: English

Table of Contents:

GENERAL

Specifications

Component Layout

Component Specifications

SYSTEM

Controller

Control System

ELU System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Control Equipment

D.Q.R Valve

Travel Device

Others (Upperstructure)

Others (Undercarriage)

6. Operators Manual (EM18M12)

Format: PDF, 308 pages

Language: English

7. Operators Manual: Quick Visual Inspection (Loader Front) (KO44502)

Format: PDF, 248 pages

Language: English

8. Operators Manual: Quick Visual Inspection (Backhoe Front) (KO41502)

Format: PDF, 248 pages

Language: English

9. Operators Manual (EM18M11)

Format: PDF, 307 pages

Language: English

10. Wiring Diagram (TT18ME00CIR)

Format: PDF, 11 pages

Language: English

Table of Contents:

EX1900-6,EX2600-6,EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (CAB)

EX1900-6(Up to serial No.1068), EX2500-6(Up to serial No.1087), EX3600-6(Up to serial No.1090) ELECTRICAL CIRCUIT DIAGRAM (ELECTRICAL EQUIPMENT BOX 1/2)

EX1900-6(Serial No.1069 and up), EX2500-6(Serial No.1088 and up), EX3600-6(Serial No.1091 and up) ELECTRICAL CIRCUIT DIAGRAM (ELECTRICAL EQUIPMENT BOX 1/2)

EX1900-6,EX2600-6,EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (ELECTRICAL EQUIPMENT BOX 2/2)

EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (MACHINE LEFT)

EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (MACHINE CENTER)

EX3600-6 ELECTRICAL CIRCUIT DIAGRAM (MACHINE RIGHT)

EX1900-6,EX2600-6,EX3600-6 ELECTRIC CONNECTORS

EX3600-6 HYDRAULIC CIRCUIT DIAGRAM (BACKHOE)(Selial No.1001)

EX3600-6 HYDRAULIC CIRCUIT DIAGRAM (BACKHOE)(Serial No.1002 AND AFTER)

EX3600-6 HYDRAULIC CIRCUIT DIAGRAM (LOADING SHOVEL)

11. Assembly Manual (KO32601)

Format: PDF, 401 pages

Language: English

Table of Contents:

1. Precautions

1-1 Safety precautions for servicemen

1-2 How to use a power wrench

1-3 Work precautions

2. Workers plan

2'. Workers plan

2-1 Transportation of Loader Front

2-1' Transportation of Backhoe Front

3. Parts check

4. Preparations (loader front)

4'. Preparations (backhoe front)

5. Machines, apparatus, tools, and materials necessary for assembly

6. Assembly of undercarriage

6-1 Preparation

6-2 Connection of track frame and side frames

6-3 Connection of travel motor piping and adjuster piping

6-4 Assembly of motor covers and step

6-5 Disassembly procedures for shipment (Procedure, Track)

6-6 Assembly of travel motor guard and mission guard(option)

7. Connection of undercarriage and superstructure

7-1 Preparations before connection

7-2 Preparation of undercarriage

7-3 Preparation of main frame

7-4 Connection of undercarriage and main frame assembly

7-5 Connection of piping to center joint

7-6 Assembly of bed (left)

7-7 Assembly of bed (right)

7-8 Installation of bed (right)

7-9 Installation of bed (left)

7-10 Assembly of engine unit

7-11 Mounting of counterweight & reserve tank

7-12 Connecting of various sections

7-13 Checking of stop valves

7-14 Final check of superstructure

7-15 Releasing air from main pumps

7-16 Trial operation of superstructure

7-17 Disassembly procedures for shipment

7-18 Assembly of parts (option)

8. Mounting procedure for loader front-end attachment

8-1 Preparation

8-2 Mounting of boom

8-3 Installation of bucket cylinders

8-4 Mounting of arm

8-5 Mounting of bucket

8-6 Releasing air from the cylinders

8-7 Adjustment of track link tension

8-8 Final trial operation check

8-9 Disassembly procedures for shipment

8'. Mounting procedure for backhoe front-end attachment

8'-1 Preparation

8'-2 Mounting of boom

8'-3 Installation of arm

8'-4 Mounting of bucket

8'-5 Releasing air from the cylinders

8'-6 Adjustment of track link tension

8'-7 Final trial operation check

8'-8 Disassembly procedures for shipment

9. Checks after completing the assembly

10. Checking machine performance

12. Check Sheets: Visual Inspection (Backhoe Front) (KO361B03)

Format: PDF, 37 pages

Language: English

13. Check Sheets: Daily and Weekly Maintenance (KO33300)

Format: PDF, 4 pages

Language: English

14. Check Sheets: Monthly Maintenance (KO33400)

Format: PDF, 73 pages

Language: English

Table of Contents:

CHECK SHEETS FOR EX3600-6

1 50 HOURS to 1250 HOURS

2 1500 HOURS to 2500 HOURS

3 2750 HOURS to 3750 HOURS

4 4000 HOURS to 5000 HOURS

5 5250 HOURS to 6250 HOURS

6 6500 HOURS to 7500 HOURS

7 7750 HOURS to 8750 HOURS

8 9000 HOURS to 10000 HOURS

9 10250 HOURS to 11250 HOURS

10 11500 HOURS to 12500 HOURS

11 12750 HOURS to 13750 HOURS

12 14000 HOURS to 15000 HOURS

13 15250 HOURS to 16250 HOURS

14 16500 HOURS to 17500 HOURS

15 17750 HOURS to 18750 HOURS

16 19000 HOURS to 20000 HOURS

EX3600-6 CHECK POINTS : 1

EX3600-6 CHECK POINTS : 2

FOR EX3600-6 PERIODIC REPLACEMENT OF RUBBER HOSES

HOW TO USE THE EX3600-6 SHEETS

15. Check Sheets: UT Inspection (Backhoe Front) (KO38401)

Format: PDF, 64 pages

Language: English

16. Check Sheets: UT Inspection (Loader Front) (KO52601)

Format: PDF, 64 pages

Language: English

17. Check Sheets: Visual Inspection (Loader Front) (KO361L03)

Format: PDF, 39 pages

Language: English

| Included in the package | |

| Workshop Manual | 3 |

| Troubleshooting Manual | 1 |

| Operational Principle Manual | 1 |

| Operators Manual | 4 |

| Wiring Diagram | 1 |

| Assembly Manual | 1 |

| Check Sheets | 6 |

| Covered | |

| Model Class | EX3600 |

| Generation | 6 |

| Truck Type | Hydraulic Excavator |

| Truck Models | EX3600-6 |

Hitachi EX3600-6 Hydraulic Excavator set of Service Manuals

- Brands Hitachi

- Product Code:Hitachi::EX3600-6

- Availability:Ready to instant download

-

$49.90

Tags: EX3600-6