All-Inclusive Factory Service Technical manual for Hitachi Wheel Loaders Models Zaxis ZW310.

This manual will assist you in troubleshooting, operating, and finding spare parts for your wheel loader.

Covered Models:

Zaxis ZW310

The manual comprises 10 documents, including the Troubleshooting Manual, Operational Principle Manual, Operators Manual, Wiring Diagram, Hydraulic Circuit Diagram, four Parts Catalogs, and Engine Parts Catalog

1. Troubleshooting Manual (ZW310_TECHNICAL_MANUEL_Troubleshooting)

Format: PDF, 569 pages

Language: English

Table of Contents:

INTRODUCTION

SAFETY

RECOGNIZE SAFETY INFORMATION

UNDERSTAND SIGNAL WORDS

FOLLOW SAFETY INSTRUCTIONS

PREPARE FOR EMERGENCIES

WEAR PROTECTIVE CLOTHING

PROTECT AGAINST NOISE

NSPECT MACHINE

GENERAL PRECAUTIONS FOR CAB

USE HANDHOLDS AND STEPS

ADJUST THE OPERATOR'S SEAT

ENSURE SAFETY BEFORE RISING FROMOR LEAVING OPERATOR’S SEAT

FASTEN YOUR SEAT BELT

MOVE AND OPERATE MACHINE SAFELY

HANDLE STARTING AIDS SAFELY

OPERATE ONLY FROM OPERATOR'SSEAT

JUMP STARTING

INVESTIGATE JOB SITE BEFOREHAND

EQUIPMENT OF HEAD GUARD, ROPS,FOPS

PROVIDE SIGNALS FOR JOBS INVOLVING MULTIPLE NUMBERS OF MACHINES

KEEP RIDERS OFF MACHINE

DRIVE SAFELY

DRIVE MACHINE SAFELY (WORK SITE)

DRIVE SAFELY WITH BUCKET LOADED

DRIVE ON SNOW SAFELY

TRAVEL ON PUBLIC ROADS SAFELY

AVOID INJURY FROM ROLLAWAY ACCIDENTS

AVOID ACCIDENTS FROM BACKING UPAND TURNING

AVOID POSITIONING BUCKET OVERANYONE

AVOID TIPPING

NEVER UNDERCUT A HIGH BANK

DIG WITH CAUTION

PERFORM TRUCK LOADING SAFELY

AVOID POWER LINES

PRECAUTIONS FOR OPERATION

PRECAUTIONS FOR LIGHTENING

OBJECT HANDLING

PROTECT AGAINST FLYING DEBRIS

PARK MACHINE SAFELY

STORE ATTACHMENTS SAFELY

TRANSPORT SAFELY

HANDLE FLUIDS SAFELY-AVOID FIRES

PRACTICE SAFE MAINTENANCE

WARN OTHERS OF SERVICE WORK

SUPPORT MACHINE PROPERLY

STAY CLEAR OF MOVING PARTS

SUPPORT MAINTENANCE PROPERLY

PREVENT PARTS FROM FLYING

PREVENT BURNS

REPLACE RUBBER HOSES PERIODICALLY

PREVENT FIRES

EVACUATING IN CASE OF FIRE

BEWARE OF EXHAUST FUMES

PRECAUTIONS FOR WELDING ANDGRINDING

AVOID HEATING NEAR PRESSURIZEDFLUID LINES

AVOID APPLYING HEAT TO LINES CONTAINING FLAMMABLE FLUIDS

REMOVE PAINT BEFORE WELDING ORHEATING

BEWARE OF ASBESTOS DUST

PREVENT BATTERY EXPLOSIONS

SERVICE AIR CONDITIONING SYSTEMSAFELY

HANDLE CHEMICAL PRODUCTS SAFELY

DISPOSE OF WASTE PROPERLY

BEFORE RETURNING THE MACHINE TOTHE CUSTOMER

SECTION AND GROUP CONTENTS

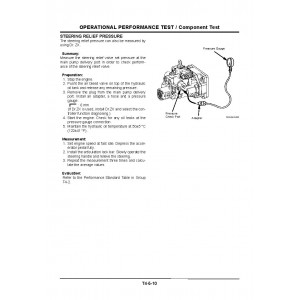

SECTION 4 OPERATIONALPERFORMANCE TEST

Group 1 Introduction

Group 2 Standard

Group 3 Engine Test

Group 4 Wheel Loader Test

Group 5 Component Test

Group 6 Adjustment

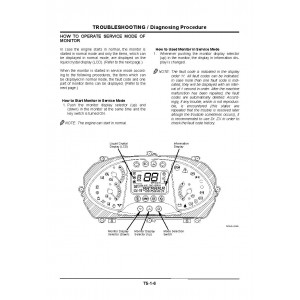

SECTION 5 TROUBLESHOOTING

Group 1 Diagnosing Procedure

Group 2 Dr.ZX

Group 3 e-Wheel

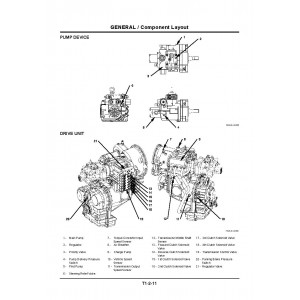

Group 4 Component Layout

Group 5 Troubleshooting A

Group 6 Troubleshooting B

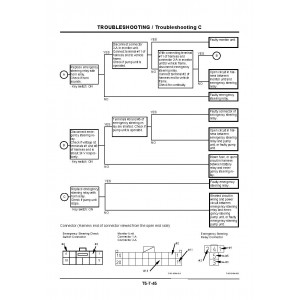

Group 7 Troubleshooting C

Group 8 Electrical System Inspection

SERVICE MANUAL REVISION REQUEST FORM

THE ATTACHED DIAGRAM LIST

2. Operational Principle Manual (ZW310_TECHNICAL_MANUEL_Operational_Principle!)

Format: PDF, 406 pages

Language: English

Table of Contents:

ZW310 TECHNICAL MANUAL Operational Principle.pdf

Operational Principle

INTRODUCTION

SECTION AND GROUPCONTENTS

GENERAL

SYSTEM

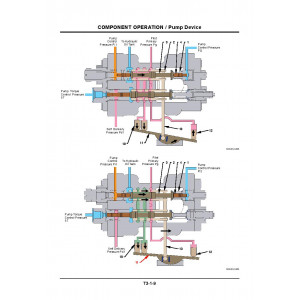

COMPONENT OPERATION

3. Operators Manual (ZW_220-250-310_OPR._EGITIMI)

Format: PDF, 330 pages

Language: English

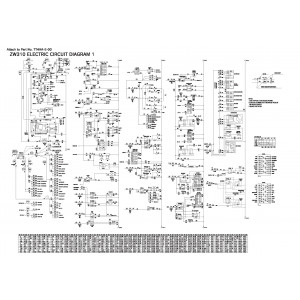

4. Wiring Diagram (zw310_TUM_DIAGRAM)

Format: PDF, 17 pages

Language: English

Table of Contents:

ELECTRIC CIRCUIT DIAGRAM 1

ELECTRIC CIRCUIT DIAGRAM 2

LIFT ARM PROXIMITY SWITCH HARNESS (EU STANDARD, GENERAL STANDARD)

LIFT ARM ANGLE SENSOR HARNESS (EU STANDARD, GENERAL STANDARD) (OPTIONAL) LIFT ARM ANGLE SENSOR HARNESS (OPTIONAL)

FRONT LIGHT HARNESS (EU STANDARD, GENERAL STANDARD)

FRONT HARNESS (EU STANDARD, GENERAL STANDARD)

CENTER HARNESS (EU STANDARD, GENERAL STANDARD)

FRONT CONSOLE HARNESS 1 (EU STANDARD, GENERAL STANDARD)

FRONT CONSOLE HARNESS 2 (EU STANDARD, GENERAL STANDARD)

SIDE CONSOLE HARNESS 1 (EU STANDARD, GENERAL STANDARD)

SIDE CONSOLE HARNESS 2 (EU STANDARD, GENERAL STANDARD) (FOR STANDARD TWO LEVER PILOT VALVE)

SIDE CONSOLE HARNESS 3 (EU STANDARD, GENERAL STANDARD) (FOR OPTIONAL JOY STICK LEVER PILOT VALVE)

REAR CONSOLE HARNESS

TRANSMISSION HARNESS (GENERAL STANDARD)

REAR FRAME HARNESS

HYDRAULIC CIRCUIT DIAGRAM (EU STANDARD)

HYDRAULIC CIRCUIT DIAGRAM (GENERAL STANDARD)

5. Hydraulic Circuit Diagram (Hitachi_ZW310_Hydraulic_Diagram)

Format: PDF, 1 page

Language: English

6. Parts Catalog (ZW310_HID.KATALOK_P4HA-E1-2)

Format: PDF, 230 pages

Language: English

Table of Contents:

PUMP

MOTOR

VALVE

CYLINDER

POWER TRAIN

OTHERS

PARTS INDEX

7. Parts Catalog (Hitachi_ZW310_Parts_Catalogue_P4HA-E1-1)

Format: PDF, 192 pages

Language: English

Table of Contents:

POWER TRAIN

CYLINDER

VALVE

OTHERS

PARTS INDEX

8. Parts Catalog (Hitachi_ZW310_Parts_Catalogue_P4HA-1-3)

Format: PDF, 597 pages

Language: English

Table of Contents:

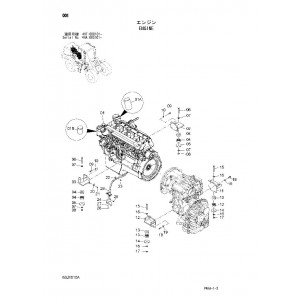

ENGINE

POWER TRAIN

CHASSIS

CAB

ELECTRICAL SYSTEM

HYDRAULIC SYSTEM

LOADER ATTACHIMENT

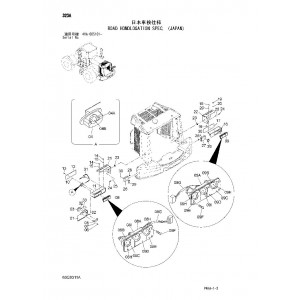

ROAD HOMOLOGATION PARTS

TOOLS

NAME-PLATE

PARTS INDEX

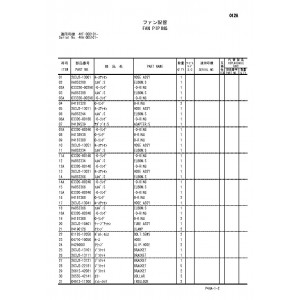

9. Parts Catalog (Hitachi_ZW310_Parts_Catalogue_P4HA-1-2)

Format: PDF, 412 pages

Language: English

Table of Contents:

ENGINE

COOLING SYSTEM

FUEL SYSTEM

EXHAUST SYSTEM

ELECTRICAL

DRIVE AXLE

PROPELLER SHAFT

TRANSMISSION

TORQUE CONVERTER

STEERING COLUMN

TIRE

POWER STEERING

BRAKE

FRAME

COVER

FLOOR BOARD

AIR CONDITIONER

CAB

SEAT

COCKPIT

MAIN PUMP

VALVE

PILOT PIPING

OIL TANK

MAIN PIPING

GREASE PIPING

TORQUE CONVERTER PIPING

LIFT ARM CYLINDER

BUCKET CYLINDER

LIFT ARM

BUCKET

DECAL

TOOLS

ROAD HOMOLOGATION SPECIFICATION

PARTS INDEX

10. Engine Parts Catalog (Hitachi_ZW310_Engine_Parts_Catalogue_PE-OM460)

Format: PDF, 62 pages

Language: English, Japan

Table of Contents:

ENGINE BODY

HEAD and VALVE MECHANISM

INLET and EXHAUST SYSTEM

LUBRICATION SYSTEM

COOLING SYSTEM

FUEL SYSTEM

ELECTRICAL PARTS

PARTS NUMBER INDEX

This manual will assist you in troubleshooting, operating, and finding spare parts for your wheel loader.

Covered Models:

Zaxis ZW310

The manual comprises 10 documents, including the Troubleshooting Manual, Operational Principle Manual, Operators Manual, Wiring Diagram, Hydraulic Circuit Diagram, four Parts Catalogs, and Engine Parts Catalog

1. Troubleshooting Manual (ZW310_TECHNICAL_MANUEL_Troubleshooting)

Format: PDF, 569 pages

Language: English

Table of Contents:

INTRODUCTION

SAFETY

RECOGNIZE SAFETY INFORMATION

UNDERSTAND SIGNAL WORDS

FOLLOW SAFETY INSTRUCTIONS

PREPARE FOR EMERGENCIES

WEAR PROTECTIVE CLOTHING

PROTECT AGAINST NOISE

NSPECT MACHINE

GENERAL PRECAUTIONS FOR CAB

USE HANDHOLDS AND STEPS

ADJUST THE OPERATOR'S SEAT

ENSURE SAFETY BEFORE RISING FROMOR LEAVING OPERATOR’S SEAT

FASTEN YOUR SEAT BELT

MOVE AND OPERATE MACHINE SAFELY

HANDLE STARTING AIDS SAFELY

OPERATE ONLY FROM OPERATOR'SSEAT

JUMP STARTING

INVESTIGATE JOB SITE BEFOREHAND

EQUIPMENT OF HEAD GUARD, ROPS,FOPS

PROVIDE SIGNALS FOR JOBS INVOLVING MULTIPLE NUMBERS OF MACHINES

KEEP RIDERS OFF MACHINE

DRIVE SAFELY

DRIVE MACHINE SAFELY (WORK SITE)

DRIVE SAFELY WITH BUCKET LOADED

DRIVE ON SNOW SAFELY

TRAVEL ON PUBLIC ROADS SAFELY

AVOID INJURY FROM ROLLAWAY ACCIDENTS

AVOID ACCIDENTS FROM BACKING UPAND TURNING

AVOID POSITIONING BUCKET OVERANYONE

AVOID TIPPING

NEVER UNDERCUT A HIGH BANK

DIG WITH CAUTION

PERFORM TRUCK LOADING SAFELY

AVOID POWER LINES

PRECAUTIONS FOR OPERATION

PRECAUTIONS FOR LIGHTENING

OBJECT HANDLING

PROTECT AGAINST FLYING DEBRIS

PARK MACHINE SAFELY

STORE ATTACHMENTS SAFELY

TRANSPORT SAFELY

HANDLE FLUIDS SAFELY-AVOID FIRES

PRACTICE SAFE MAINTENANCE

WARN OTHERS OF SERVICE WORK

SUPPORT MACHINE PROPERLY

STAY CLEAR OF MOVING PARTS

SUPPORT MAINTENANCE PROPERLY

PREVENT PARTS FROM FLYING

PREVENT BURNS

REPLACE RUBBER HOSES PERIODICALLY

PREVENT FIRES

EVACUATING IN CASE OF FIRE

BEWARE OF EXHAUST FUMES

PRECAUTIONS FOR WELDING ANDGRINDING

AVOID HEATING NEAR PRESSURIZEDFLUID LINES

AVOID APPLYING HEAT TO LINES CONTAINING FLAMMABLE FLUIDS

REMOVE PAINT BEFORE WELDING ORHEATING

BEWARE OF ASBESTOS DUST

PREVENT BATTERY EXPLOSIONS

SERVICE AIR CONDITIONING SYSTEMSAFELY

HANDLE CHEMICAL PRODUCTS SAFELY

DISPOSE OF WASTE PROPERLY

BEFORE RETURNING THE MACHINE TOTHE CUSTOMER

SECTION AND GROUP CONTENTS

SECTION 4 OPERATIONALPERFORMANCE TEST

Group 1 Introduction

Group 2 Standard

Group 3 Engine Test

Group 4 Wheel Loader Test

Group 5 Component Test

Group 6 Adjustment

SECTION 5 TROUBLESHOOTING

Group 1 Diagnosing Procedure

Group 2 Dr.ZX

Group 3 e-Wheel

Group 4 Component Layout

Group 5 Troubleshooting A

Group 6 Troubleshooting B

Group 7 Troubleshooting C

Group 8 Electrical System Inspection

SERVICE MANUAL REVISION REQUEST FORM

THE ATTACHED DIAGRAM LIST

2. Operational Principle Manual (ZW310_TECHNICAL_MANUEL_Operational_Principle!)

Format: PDF, 406 pages

Language: English

Table of Contents:

ZW310 TECHNICAL MANUAL Operational Principle.pdf

Operational Principle

INTRODUCTION

SECTION AND GROUPCONTENTS

GENERAL

SYSTEM

COMPONENT OPERATION

3. Operators Manual (ZW_220-250-310_OPR._EGITIMI)

Format: PDF, 330 pages

Language: English

4. Wiring Diagram (zw310_TUM_DIAGRAM)

Format: PDF, 17 pages

Language: English

Table of Contents:

ELECTRIC CIRCUIT DIAGRAM 1

ELECTRIC CIRCUIT DIAGRAM 2

LIFT ARM PROXIMITY SWITCH HARNESS (EU STANDARD, GENERAL STANDARD)

LIFT ARM ANGLE SENSOR HARNESS (EU STANDARD, GENERAL STANDARD) (OPTIONAL) LIFT ARM ANGLE SENSOR HARNESS (OPTIONAL)

FRONT LIGHT HARNESS (EU STANDARD, GENERAL STANDARD)

FRONT HARNESS (EU STANDARD, GENERAL STANDARD)

CENTER HARNESS (EU STANDARD, GENERAL STANDARD)

FRONT CONSOLE HARNESS 1 (EU STANDARD, GENERAL STANDARD)

FRONT CONSOLE HARNESS 2 (EU STANDARD, GENERAL STANDARD)

SIDE CONSOLE HARNESS 1 (EU STANDARD, GENERAL STANDARD)

SIDE CONSOLE HARNESS 2 (EU STANDARD, GENERAL STANDARD) (FOR STANDARD TWO LEVER PILOT VALVE)

SIDE CONSOLE HARNESS 3 (EU STANDARD, GENERAL STANDARD) (FOR OPTIONAL JOY STICK LEVER PILOT VALVE)

REAR CONSOLE HARNESS

TRANSMISSION HARNESS (GENERAL STANDARD)

REAR FRAME HARNESS

HYDRAULIC CIRCUIT DIAGRAM (EU STANDARD)

HYDRAULIC CIRCUIT DIAGRAM (GENERAL STANDARD)

5. Hydraulic Circuit Diagram (Hitachi_ZW310_Hydraulic_Diagram)

Format: PDF, 1 page

Language: English

6. Parts Catalog (ZW310_HID.KATALOK_P4HA-E1-2)

Format: PDF, 230 pages

Language: English

Table of Contents:

PUMP

MOTOR

VALVE

CYLINDER

POWER TRAIN

OTHERS

PARTS INDEX

7. Parts Catalog (Hitachi_ZW310_Parts_Catalogue_P4HA-E1-1)

Format: PDF, 192 pages

Language: English

Table of Contents:

POWER TRAIN

CYLINDER

VALVE

OTHERS

PARTS INDEX

8. Parts Catalog (Hitachi_ZW310_Parts_Catalogue_P4HA-1-3)

Format: PDF, 597 pages

Language: English

Table of Contents:

ENGINE

POWER TRAIN

CHASSIS

CAB

ELECTRICAL SYSTEM

HYDRAULIC SYSTEM

LOADER ATTACHIMENT

ROAD HOMOLOGATION PARTS

TOOLS

NAME-PLATE

PARTS INDEX

9. Parts Catalog (Hitachi_ZW310_Parts_Catalogue_P4HA-1-2)

Format: PDF, 412 pages

Language: English

Table of Contents:

ENGINE

COOLING SYSTEM

FUEL SYSTEM

EXHAUST SYSTEM

ELECTRICAL

DRIVE AXLE

PROPELLER SHAFT

TRANSMISSION

TORQUE CONVERTER

STEERING COLUMN

TIRE

POWER STEERING

BRAKE

FRAME

COVER

FLOOR BOARD

AIR CONDITIONER

CAB

SEAT

COCKPIT

MAIN PUMP

VALVE

PILOT PIPING

OIL TANK

MAIN PIPING

GREASE PIPING

TORQUE CONVERTER PIPING

LIFT ARM CYLINDER

BUCKET CYLINDER

LIFT ARM

BUCKET

DECAL

TOOLS

ROAD HOMOLOGATION SPECIFICATION

PARTS INDEX

10. Engine Parts Catalog (Hitachi_ZW310_Engine_Parts_Catalogue_PE-OM460)

Format: PDF, 62 pages

Language: English, Japan

Table of Contents:

ENGINE BODY

HEAD and VALVE MECHANISM

INLET and EXHAUST SYSTEM

LUBRICATION SYSTEM

COOLING SYSTEM

FUEL SYSTEM

ELECTRICAL PARTS

PARTS NUMBER INDEX

| Included in the package | |

| Troubleshooting Manual | 1 |

| Operational Principle Manual | 1 |

| Operators Manual | 1 |

| Wiring Diagram | 1 |

| Hydraulic Circuit Diagram | 1 |

| Parts Catalog | 4 |

| Engine Parts Catalog | 1 |

| Covered | |

| Model Class | ZW310 |

| Generation | 1 |

| Truck Type | Wheel Loader |

| Truck Models | ZW310 |

Hitachi Zaxis ZW310 Wheel Loader set of Service Manuals

- Brands Hitachi

- Product Code:Hitachi::ZW310

- Availability:Ready to instant download

-

$23.00

Tags: Zaxis ZW310.

.pdf-1-300x300.jpg)

.pdf-13-300x300.jpg)

.pdf-49-300x300.jpg)

.pdf-44-300x300.jpg)