All-Inclusive Factory Service Technical manual for Hitachi Crawler Excavators Models Zaxis 800 and Zaxis 850H.

This manuals will assist you in diagnosing, repairing, performing perfomance checks, troubleshooting, maintaining, operating, and assembling for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 800

Zaxis 850H

The manual comprises 8 documents, including two Workshop Manuals, the Perfomance Check and Troubleshooting Manual, Maintenance Manual, Operational Principle Manual, Operators Manual, Wiring Diagram, and Assembly Manual

1. Workshop Manual (W17VE-00_updated+information_1pages)

Format: PDF, 1 page

Language: English

2. Workshop Manual (W17VE-00)

Format: PDF, 624 pages

Language: English

Table of Contents:

General Information

General Repair Instruction

Illustration Arrows

Abbreviations

Nut and Bolt Angular Tightening Method

Standard Bolt Torque Specifications

Recommended Thread Locking Agents

Main Data and Specifications

Engine External Drawing

Service Standard

Torque Specifications

Special Tools

Troubleshooting

Lubricant Application

Sealant Application

SERVICE INFORMATION

Identification

Lubrication System

Fuel System

Cooling System

Valve Clearance Adjustment

Compression Pressure Measurement

Recommended Lubricants

Engine Oil Viscosity Chart

ENGINE MECHANICAL

Service Precautions

General Description

Engine Cleanliness and Care

General Information on Engine Service

FanCenter

Turbocharger

ExhaustManifold

InletManifold

Water Pump

Alternator

Oil Cooler

Injection Pump

Coupling Assembly

Cylinder Head

Rocker Arm and Shaft Assembly

Camshaft

Timing Gears

Flywheel Housing

Oil Pan

Piston

Crankshaft

Crank Pulley

Flywheel

Cylinder Block

ENGINE COOLING

Service Precaution

General Description

Water Pump

Thermostat

ENGINE FUEL

Service Precaution

General Description

Fuel Filter

Injection Nozzle Holder

Injection Pump

STARTING AND CHARGING

Service Precaution

Alternator

Starter Motor

ENGINE LUBRICATION

Service Precaution

General Description

Oil Pump

Oil Cooler

Main Oil Filter

Partial Oil Filter

ENGINE INDUCTION

Service Precaution

Turbocharger

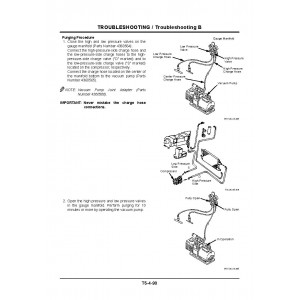

3. Perfomance Check and Troubleshooting Manual (TTLA0503)

Format: PDF, 319 pages

Language: English

Table of Contents:

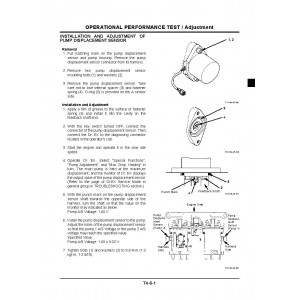

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Component Test

Adjustment

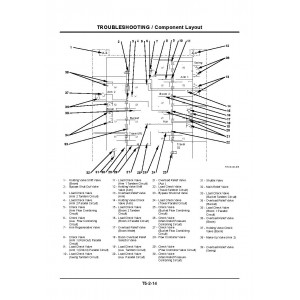

TROUBLESHOOTING

General

Component Layout

Troubleshooting A

Troubleshooting B

Troubleshooting C

Electrical System Inspection

ICX

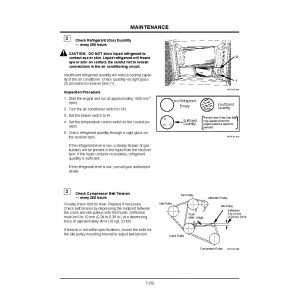

4. Maintenance Manual (TTLA0505)

Format: PDF, 177 pages

Language: English

Table of Contents:

ASSEMBLING

PRECAUTIONS FOR ASSEMBLING

PRECAUTIONS FOR SLINGING WORK

PRECAUTIONS FOR OPERATING MACHINE

INSTALLING COUNTERWEIGHT

INSTALLING BOOM CYLINDER (BACKHOE)

INSTALLING BOOM (BACKHOE)

CONNECTING HOSES BETWEEN BOOM AND MACHINE (BACKHOE)

INSTALLING BOOM CYLINDER ROD (BACKHOE)

INSTALLING ARM (BACKHOE)

CONNECTING ARM CYLINDER ROD (BACKHOE)

CONNECTING BUCKET CYLINDER HOSES (BACKHOE)

INSTALLING BUCKET (BACKHOE)

CONNECTING PIPINGS (LOADING SHOVEL)

INSTALLING LOADING SHOVEL FRONT

REMOVING STOPPER AND WIRE (LOADING SHOVEL)

CONNECTING HOSES BETWEEN BOOM AND MACHINE (LOADING SHOVEL)

INSTALLING BOOM CYLINDER (LOADING SHOVEL)

BLEEDING AIR FROM ARM AND BUCKET CYLINDERS (LOADING SHOVEL)

INSTALLING LOADING SHOVEL BUCKET

CONNECTING DUMP CYLINDER HOSE (LOADING SHOVEL)

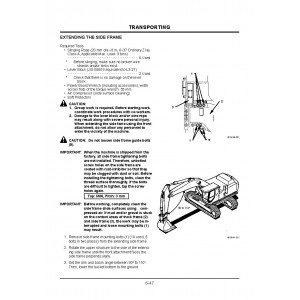

EXTENDING THE SIDE FRAME

TRANSPORTING

TRANSPORTING BY ROAD

TRANSPORTING THE MACHINE BY TRAILER

LOADING/UNLOADING ON A TRAILER

TYPES OF PACKINGS FOR TRANSPORTATION

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-1 (BACKHOE)

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-2 (BACKHOE)

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-1 (LOADING SHOVEL)

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-2 (LOADING SHOVEL)

RETRACTING OR EXTENDING THE SIDE FRAME

RETRACTING THE SIDE FRAME

EXTENDING THE SIDE FRAME

MAINTENANCE

CORRECT MAINTENANCE AND INSPECTION PROCEDURES

CHECK THE HOUR METER REGULARLY

USE CORRECT FUELS AND LUBRICANTS

PREPARE MACHINE FOR MAINTENANCE

HOOD AND ACCESS COVERS

PERIODIC REPLACEMENT OF PARTS

USE ELECTRICAL OUTLET (OPTIONAL)

HYDRAULIC SYSTEM

MAIN CIRCUIT (BACKHOE)

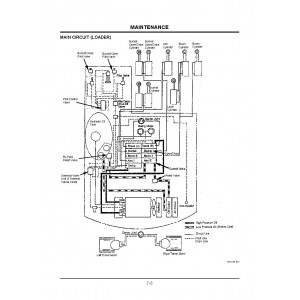

MAIN CIRCUIT (LOADER)

ZX800 ELECTRICAL CIRCUIT DIAGRAM

MAINTENANCE GUIDE

J. MISCELLANEOUS

Check Bucket Teeth

Change Bucket

Adjust Bucket Linkage

Remove the Travel Levers

Check and Replace Seat Belt Check

Check Windshield Washer Fluid Level

Check Track Sag

Adjust Track Sag Precautions for Adjusting Track Sag

Clean Cab Floor

Check Tightening Torque of Bolts and Nuts

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

STORING THE MACHINE

REMOVING THE MACHINE FROM STORAGE

INSTALLING VANDAL-PROOF COVERS

HELP PREVENT CRIME

RECORD IDENTIFICATION NUMBERS

KEEP PROOF OF OWNERSHIP

PARK INDOORS OUT OF SIGHT

WHEN PARKING OUTDOORS

REDUCE VANDALISM

REPORT THEFTS IMMEDIATELY

TROUBLESHOOTING

ENGINE

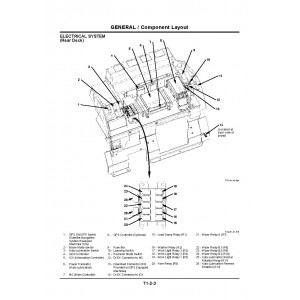

ELECTRICAL SYSTEM

MODE SELECTION

CONTROL LEVERS

HYDRAULIC SYSTEM

PUMP CONTROL SYSTEM

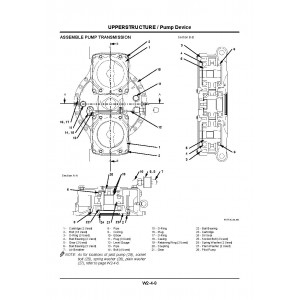

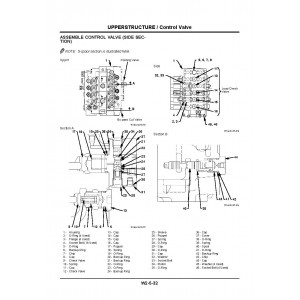

5. Operational Principle Manual (TTLA0502)

Format: PDF, 213 pages

Language: English

Table of Contents:

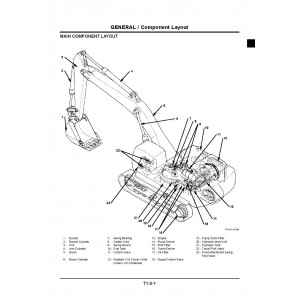

GENERAL

Specification

Component Layout

Component Specifications

SYSTEM

Control System

Hydraulic System

Electrical System

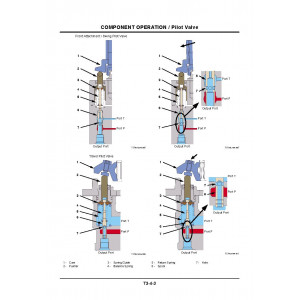

COMPONENT OPERATION

Pump Device

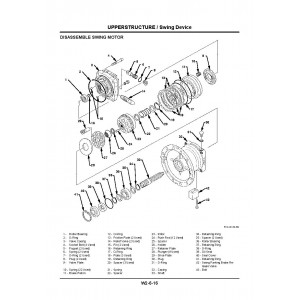

Swing Device

Control Valve

Pilot Valve

Travel Device

Signal Control Valve

Others (Upperstructure)

Others (Undercarriage)

6. Operators Manual (TTLA0504)

Format: PDF, 115 pages

Language: English

Table of Contents:

OPERATOR'S STATION

CAB FEATURES

MONITOR PANEL

SWITCH PANEL

SWITCH PANEL

KEY SWITCH

QUICK-IDLE SWITCH

HORN SWITCH

CIGER LIGHTER

CAB LIGHT

INSTALLING FIRE EXTINGUISHER

PILOT CONTROL SHUT-OFF LEVER

ENGINE STOP KNOB

FUSE BOX

AIR CONDITIONER OPERATION

AUTO AIR CONDITIONER

CAB HEATER OPERATION

COOLING OPERATION

DEFROSTER OPERATION

TIPS FOR OPTIMAL AIR CONDITIONER USAGE

AM/FM RADIO OPERATION

DIGITAL CLOCK SETTING PROCEDURE

CAB DOOR RELEASE LEVER

OPENING UPPER FRONT WINDOW (ZAXIS800)

CLOSING UPPER FRONT WINDOW (ZAXIS800)

REMOVING AND STORING LOWER FRONT WINDOW (ZAXIS800)

OPENING SIDE WINDOWS (ZAXIS800)

OPENING/CLOSING OVERHEAD WINDOW (ZAXIS800)

EMERGENCY EXIT (ZAXIS800)

HEADGUARD-INTEGRATED CAB (ZAXIS850H)

EMERGENCY EXIT (HEAD- GUARD-INTEGRATED CAB) (ZAXIS850H)

ADJUSTING THE SEAT

ADJUSTING CONSOLE HEIGHT

SEAT BELT

BREAK-IN

OBSERVE ENGINE OPERATION CLOSELY

EVERY EIGHT HOURS OR DAILY

AFTER THE FIRST 50 HOURS

AFTER THE FIRST 100 HOURS

OPERATING THE ENGINE

INSPECT MACHINE DAILY BEFORE STARTING

BEFORE STARTING ENGINE

LEVEL CHECK

STARTING THE ENGINE

STARTING IN COLD WEATHER

CHECK INSTRUMENTS AFTER STARTING

USING BOOSTER BATTERIES

STOPPING THE ENGINE

DRIVING THE MACHINE

DRIVE THE MACHINE CAREFULLY

STEERING THE MACHINE USING PEDALS

STEERING THE MACHINE USING LEVERS

TRAVEL MODE SWITCH

TRAVEL ALARM (Optional)

TRAVELING

OPERATING ON SOFT GROUND

RAISE ONE TRACK USING BOOM AND ARM

TOWING MACHINE A SHORT DISTANCE

OPERATING IN WATER OR MUD

PRECAUTIONS FOR TRAVELING ON SLOPES

PARKING THE MACHINE ON SLOPES

PARKING THE MACHINE

OPERATING THE MACHINE

CONTROL LEVER (ISO PATTERN)

CONTROL LEVER (HITACHI PATTERN)

CONTROL LEVER(ISO PATTERN LOADING SHOVEL)

CONTROL LEVER(HITACHI PATTERN LOADING SHOVEL)

BUCKET OPEN-CLOSE PEDALS (LOADING SHOVEL)

PILOT CONTROL SHUT-OFF LEVER

ENGINE SPEED CONTROL

AUTO-IDLE

AUTO-ACCELERATION

WORK MODE

QUICK-IDLE

POWER MODE

PRECAUTIONS FOR OPERATIONS

OPERATE THE MACHINE SAFELY

OPERATING BACKHOE

GRADING OPERATION

FACE SHOVEL OPERATION

AVOID ABUSIVE OPERATION

OPERATING TIPS

SELECT CORRECT TRACK SHOES

PRECAUTION FOR ARM ROLL-IN/ BUCKET ROLL-IN COMBINED OPERATION

LOADING SHOVEL OPERATION

STRAIGHT RETRACTION OPERATION

PROHIBITED OPERATIONS (LOADING SHOVEL)

PRECAUTIONS FOR OPERATION (LOADING SHOVEL)

OBJECT HANDLING --- IF EQUIPPED

ELECTRONIC CONTROL SYSTEM BYPASS PROCEDURE

OVERNIGHT STORAGE INSTRUCTIONS

OPTIONAL ATTACHMENTS AND DEVICES

HYDRAULIC BREAKER

BREAKER OPERATION

PRECAUTIONS FOR BREAKER OPERATION

BREAKER MAINTENANCE

REPLACE BREAKER CIRCUIT RETURN OIL FILTER

HYDRAULIC CRUSHER

PRECAUTIONS FOR CRUSHER OPERATION

7. Wiring Diagram (ZX800_elec_hyd)

Format: PDF, 9 pages

Language: English

8. Assembly Manual (KO-282-00)

Format: PDF, 210 pages

Language: English

Table of Contents:

COVER

Foreword

ZX800/ ZX850H Assembly Chart BACKHOE FRONT

ZX800/ ZX850H Assembly Chart BACKHOE FRONT

ZX800/ ZX850H Assembly Chart LOADER FRONT

ZX800/ ZX850H Assembly Chart LOADER FRONT

1. Precautions

2. Work Plan and Preparations

3. Parts check

4. Preparations

5. Machines, apparatuses, tools, and materials necessary for assembly

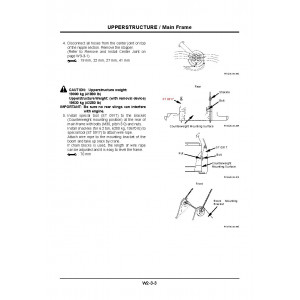

ASSEMBLY OF SUPERSTRUCTURE

MOUNTING PROCEDURE FOR FRONT-END ATTACHMENTS BACKHOE FRONT

MOUNTING PROCEDURE FOR FRONT-END ATTACHMENTS LOADER FRONT

9. Extending and retracting the side frames

CHECKS & PERFORMANCE STANDARDS

12. Appendix (Lifting Diagrams)

BACK COVER

This manuals will assist you in diagnosing, repairing, performing perfomance checks, troubleshooting, maintaining, operating, and assembling for your crawler excavator.

You can use a Windows, Mac, or Android device to view this manuals. You only need to have a PDF reader installed.

Covered Models:

Zaxis 800

Zaxis 850H

The manual comprises 8 documents, including two Workshop Manuals, the Perfomance Check and Troubleshooting Manual, Maintenance Manual, Operational Principle Manual, Operators Manual, Wiring Diagram, and Assembly Manual

1. Workshop Manual (W17VE-00_updated+information_1pages)

Format: PDF, 1 page

Language: English

2. Workshop Manual (W17VE-00)

Format: PDF, 624 pages

Language: English

Table of Contents:

General Information

General Repair Instruction

Illustration Arrows

Abbreviations

Nut and Bolt Angular Tightening Method

Standard Bolt Torque Specifications

Recommended Thread Locking Agents

Main Data and Specifications

Engine External Drawing

Service Standard

Torque Specifications

Special Tools

Troubleshooting

Lubricant Application

Sealant Application

SERVICE INFORMATION

Identification

Lubrication System

Fuel System

Cooling System

Valve Clearance Adjustment

Compression Pressure Measurement

Recommended Lubricants

Engine Oil Viscosity Chart

ENGINE MECHANICAL

Service Precautions

General Description

Engine Cleanliness and Care

General Information on Engine Service

FanCenter

Turbocharger

ExhaustManifold

InletManifold

Water Pump

Alternator

Oil Cooler

Injection Pump

Coupling Assembly

Cylinder Head

Rocker Arm and Shaft Assembly

Camshaft

Timing Gears

Flywheel Housing

Oil Pan

Piston

Crankshaft

Crank Pulley

Flywheel

Cylinder Block

ENGINE COOLING

Service Precaution

General Description

Water Pump

Thermostat

ENGINE FUEL

Service Precaution

General Description

Fuel Filter

Injection Nozzle Holder

Injection Pump

STARTING AND CHARGING

Service Precaution

Alternator

Starter Motor

ENGINE LUBRICATION

Service Precaution

General Description

Oil Pump

Oil Cooler

Main Oil Filter

Partial Oil Filter

ENGINE INDUCTION

Service Precaution

Turbocharger

3. Perfomance Check and Troubleshooting Manual (TTLA0503)

Format: PDF, 319 pages

Language: English

Table of Contents:

OPERATIONAL PERFORMANCE TEST

Introduction

Standard

Engine Test

Excavator Test

Component Test

Adjustment

TROUBLESHOOTING

General

Component Layout

Troubleshooting A

Troubleshooting B

Troubleshooting C

Electrical System Inspection

ICX

4. Maintenance Manual (TTLA0505)

Format: PDF, 177 pages

Language: English

Table of Contents:

ASSEMBLING

PRECAUTIONS FOR ASSEMBLING

PRECAUTIONS FOR SLINGING WORK

PRECAUTIONS FOR OPERATING MACHINE

INSTALLING COUNTERWEIGHT

INSTALLING BOOM CYLINDER (BACKHOE)

INSTALLING BOOM (BACKHOE)

CONNECTING HOSES BETWEEN BOOM AND MACHINE (BACKHOE)

INSTALLING BOOM CYLINDER ROD (BACKHOE)

INSTALLING ARM (BACKHOE)

CONNECTING ARM CYLINDER ROD (BACKHOE)

CONNECTING BUCKET CYLINDER HOSES (BACKHOE)

INSTALLING BUCKET (BACKHOE)

CONNECTING PIPINGS (LOADING SHOVEL)

INSTALLING LOADING SHOVEL FRONT

REMOVING STOPPER AND WIRE (LOADING SHOVEL)

CONNECTING HOSES BETWEEN BOOM AND MACHINE (LOADING SHOVEL)

INSTALLING BOOM CYLINDER (LOADING SHOVEL)

BLEEDING AIR FROM ARM AND BUCKET CYLINDERS (LOADING SHOVEL)

INSTALLING LOADING SHOVEL BUCKET

CONNECTING DUMP CYLINDER HOSE (LOADING SHOVEL)

EXTENDING THE SIDE FRAME

TRANSPORTING

TRANSPORTING BY ROAD

TRANSPORTING THE MACHINE BY TRAILER

LOADING/UNLOADING ON A TRAILER

TYPES OF PACKINGS FOR TRANSPORTATION

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-1 (BACKHOE)

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-2 (BACKHOE)

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-1 (LOADING SHOVEL)

PACKING DIMENSIONS AND WEIGHTS FOR TRANSPORTATION-2 (LOADING SHOVEL)

RETRACTING OR EXTENDING THE SIDE FRAME

RETRACTING THE SIDE FRAME

EXTENDING THE SIDE FRAME

MAINTENANCE

CORRECT MAINTENANCE AND INSPECTION PROCEDURES

CHECK THE HOUR METER REGULARLY

USE CORRECT FUELS AND LUBRICANTS

PREPARE MACHINE FOR MAINTENANCE

HOOD AND ACCESS COVERS

PERIODIC REPLACEMENT OF PARTS

USE ELECTRICAL OUTLET (OPTIONAL)

HYDRAULIC SYSTEM

MAIN CIRCUIT (BACKHOE)

MAIN CIRCUIT (LOADER)

ZX800 ELECTRICAL CIRCUIT DIAGRAM

MAINTENANCE GUIDE

J. MISCELLANEOUS

Check Bucket Teeth

Change Bucket

Adjust Bucket Linkage

Remove the Travel Levers

Check and Replace Seat Belt Check

Check Windshield Washer Fluid Level

Check Track Sag

Adjust Track Sag Precautions for Adjusting Track Sag

Clean Cab Floor

Check Tightening Torque of Bolts and Nuts

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

MAINTENANCE UNDER SPECIAL ENVIRONMENTAL CONDITIONS

STORAGE

STORING THE MACHINE

REMOVING THE MACHINE FROM STORAGE

INSTALLING VANDAL-PROOF COVERS

HELP PREVENT CRIME

RECORD IDENTIFICATION NUMBERS

KEEP PROOF OF OWNERSHIP

PARK INDOORS OUT OF SIGHT

WHEN PARKING OUTDOORS

REDUCE VANDALISM

REPORT THEFTS IMMEDIATELY

TROUBLESHOOTING

ENGINE

ELECTRICAL SYSTEM

MODE SELECTION

CONTROL LEVERS

HYDRAULIC SYSTEM

PUMP CONTROL SYSTEM

5. Operational Principle Manual (TTLA0502)

Format: PDF, 213 pages

Language: English

Table of Contents:

GENERAL

Specification

Component Layout

Component Specifications

SYSTEM

Control System

Hydraulic System

Electrical System

COMPONENT OPERATION

Pump Device

Swing Device

Control Valve

Pilot Valve

Travel Device

Signal Control Valve

Others (Upperstructure)

Others (Undercarriage)

6. Operators Manual (TTLA0504)

Format: PDF, 115 pages

Language: English

Table of Contents:

OPERATOR'S STATION

CAB FEATURES

MONITOR PANEL

SWITCH PANEL

SWITCH PANEL

KEY SWITCH

QUICK-IDLE SWITCH

HORN SWITCH

CIGER LIGHTER

CAB LIGHT

INSTALLING FIRE EXTINGUISHER

PILOT CONTROL SHUT-OFF LEVER

ENGINE STOP KNOB

FUSE BOX

AIR CONDITIONER OPERATION

AUTO AIR CONDITIONER

CAB HEATER OPERATION

COOLING OPERATION

DEFROSTER OPERATION

TIPS FOR OPTIMAL AIR CONDITIONER USAGE

AM/FM RADIO OPERATION

DIGITAL CLOCK SETTING PROCEDURE

CAB DOOR RELEASE LEVER

OPENING UPPER FRONT WINDOW (ZAXIS800)

CLOSING UPPER FRONT WINDOW (ZAXIS800)

REMOVING AND STORING LOWER FRONT WINDOW (ZAXIS800)

OPENING SIDE WINDOWS (ZAXIS800)

OPENING/CLOSING OVERHEAD WINDOW (ZAXIS800)

EMERGENCY EXIT (ZAXIS800)

HEADGUARD-INTEGRATED CAB (ZAXIS850H)

EMERGENCY EXIT (HEAD- GUARD-INTEGRATED CAB) (ZAXIS850H)

ADJUSTING THE SEAT

ADJUSTING CONSOLE HEIGHT

SEAT BELT

BREAK-IN

OBSERVE ENGINE OPERATION CLOSELY

EVERY EIGHT HOURS OR DAILY

AFTER THE FIRST 50 HOURS

AFTER THE FIRST 100 HOURS

OPERATING THE ENGINE

INSPECT MACHINE DAILY BEFORE STARTING

BEFORE STARTING ENGINE

LEVEL CHECK

STARTING THE ENGINE

STARTING IN COLD WEATHER

CHECK INSTRUMENTS AFTER STARTING

USING BOOSTER BATTERIES

STOPPING THE ENGINE

DRIVING THE MACHINE

DRIVE THE MACHINE CAREFULLY

STEERING THE MACHINE USING PEDALS

STEERING THE MACHINE USING LEVERS

TRAVEL MODE SWITCH

TRAVEL ALARM (Optional)

TRAVELING

OPERATING ON SOFT GROUND

RAISE ONE TRACK USING BOOM AND ARM

TOWING MACHINE A SHORT DISTANCE

OPERATING IN WATER OR MUD

PRECAUTIONS FOR TRAVELING ON SLOPES

PARKING THE MACHINE ON SLOPES

PARKING THE MACHINE

OPERATING THE MACHINE

CONTROL LEVER (ISO PATTERN)

CONTROL LEVER (HITACHI PATTERN)

CONTROL LEVER(ISO PATTERN LOADING SHOVEL)

CONTROL LEVER(HITACHI PATTERN LOADING SHOVEL)

BUCKET OPEN-CLOSE PEDALS (LOADING SHOVEL)

PILOT CONTROL SHUT-OFF LEVER

ENGINE SPEED CONTROL

AUTO-IDLE

AUTO-ACCELERATION

WORK MODE

QUICK-IDLE

POWER MODE

PRECAUTIONS FOR OPERATIONS

OPERATE THE MACHINE SAFELY

OPERATING BACKHOE

GRADING OPERATION

FACE SHOVEL OPERATION

AVOID ABUSIVE OPERATION

OPERATING TIPS

SELECT CORRECT TRACK SHOES

PRECAUTION FOR ARM ROLL-IN/ BUCKET ROLL-IN COMBINED OPERATION

LOADING SHOVEL OPERATION

STRAIGHT RETRACTION OPERATION

PROHIBITED OPERATIONS (LOADING SHOVEL)

PRECAUTIONS FOR OPERATION (LOADING SHOVEL)

OBJECT HANDLING --- IF EQUIPPED

ELECTRONIC CONTROL SYSTEM BYPASS PROCEDURE

OVERNIGHT STORAGE INSTRUCTIONS

OPTIONAL ATTACHMENTS AND DEVICES

HYDRAULIC BREAKER

BREAKER OPERATION

PRECAUTIONS FOR BREAKER OPERATION

BREAKER MAINTENANCE

REPLACE BREAKER CIRCUIT RETURN OIL FILTER

HYDRAULIC CRUSHER

PRECAUTIONS FOR CRUSHER OPERATION

7. Wiring Diagram (ZX800_elec_hyd)

Format: PDF, 9 pages

Language: English

8. Assembly Manual (KO-282-00)

Format: PDF, 210 pages

Language: English

Table of Contents:

COVER

Foreword

ZX800/ ZX850H Assembly Chart BACKHOE FRONT

ZX800/ ZX850H Assembly Chart BACKHOE FRONT

ZX800/ ZX850H Assembly Chart LOADER FRONT

ZX800/ ZX850H Assembly Chart LOADER FRONT

1. Precautions

2. Work Plan and Preparations

3. Parts check

4. Preparations

5. Machines, apparatuses, tools, and materials necessary for assembly

ASSEMBLY OF SUPERSTRUCTURE

MOUNTING PROCEDURE FOR FRONT-END ATTACHMENTS BACKHOE FRONT

MOUNTING PROCEDURE FOR FRONT-END ATTACHMENTS LOADER FRONT

9. Extending and retracting the side frames

CHECKS & PERFORMANCE STANDARDS

12. Appendix (Lifting Diagrams)

BACK COVER

| Included in the package | |

| Workshop Manual | 2 |

| Perfomance Check and Troubleshooting Manual | 1 |

| Maintenance Manual | 1 |

| Operational Principle Manual | 1 |

| Operators Manual | 1 |

| Wiring Diagram | 1 |

| Assembly Manual | 1 |

| Covered | |

| Model Class | ZAXIS 800, ZAXIS 850 |

| Generation | 1 |

| Truck Type | Crawler Excavator |

| Truck Models | ZAXIS 800, ZAXIS 850H |

Hitachi Zaxis 800 and Zaxis 850H Crawler Excavator set of Service Manuals

- Brands Hitachi

- Product Code:Hitachi::ZX800

- Availability:Ready to instant download

-

$23.00

Tags: Zaxis 800, Zaxis 850H